I just purchased a 458 Winchester made by Whitworth off of guns international. I’m anticipating its arrival. There seems to be mixed emotions about the cartridge. I’d like to hear some real examples. It seemed to have significantly decreased the African elephant population along with the 308 FAL through culling operations in the second half of the last century. So it must have some merit. Please weigh in if you have used it on game including and up too Buffalo.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Love or Hate for the 458 Winchester

- Thread starter GoexFFG

- Start date

rigby 416

AH member

- Joined

- Jun 24, 2021

- Messages

- 21

- Reaction score

- 41

- Location

- Geelong Aust

- Member of

- ssaa, field and game.

- Hunted

- sambar deer.

With newer powders about know it is still a great cartridge.

matt85

AH legend

From what I understand the cartridge originally had major issues with case capacity. These seem to have been mostly solved with better powders becoming available.

458 Exp

AH senior member

- Joined

- Apr 30, 2021

- Messages

- 72

- Reaction score

- 340

- Location

- Randburg

- Member of

- CHASA, BASA,

- Hunted

- South Africa, Tanzania, Namibia

I personally feel the 458 Win Mag should’ve been loaded from day one with a good quality 450gr bullet and never a 500gr.

Dropping that 50gr in bullet weigh gives you case volume and the extra velocity that the 50”gr is lacking.

Dropping that 50gr in bullet weigh gives you case volume and the extra velocity that the 50”gr is lacking.

Mtn_Infantry

AH elite

Love the Black Powder reference in the name choice

Most of the bad rep comes from ammo when 458WM was first launched. This has been resolved for the most part with modern factory loads, or handloads. You’ve got a fine rifle and fine caliber for anything you might want in Africa. If you decide you don’t like it, you can always rechamber to a 458Lott or do a 450 Rigby.

Most of the bad rep comes from ammo when 458WM was first launched. This has been resolved for the most part with modern factory loads, or handloads. You’ve got a fine rifle and fine caliber for anything you might want in Africa. If you decide you don’t like it, you can always rechamber to a 458Lott or do a 450 Rigby.

Mtn_Infantry

AH elite

Thanks for the correction. I was thinking whitworth might be a magnum Mauser action.458 winchester action is not big enough for 458 lott or 450 rigby. If it is cz 550 manum action you can.

Krish

Hunter-Habib

AH legend

The answer to this question needs very careful historical and ballistic assessment.

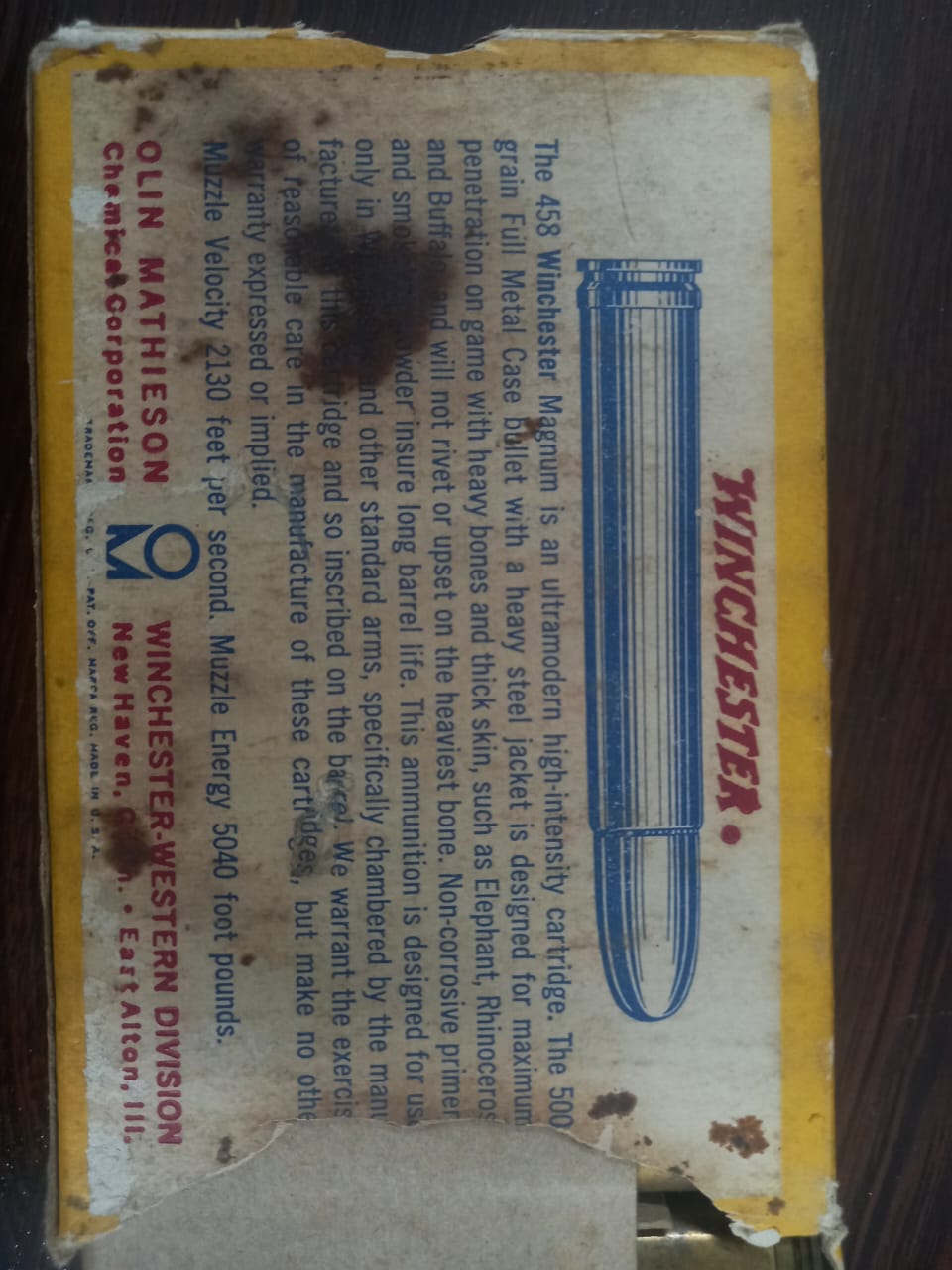

When Winchester introduced their .458 Winchester Magnum caliber in 1956, velocities were advertised as 2130 fps (although the actual chronographed velocity was 2087 fps when fired from the 25” barrel of a Winchester Model 70 as per an H.P White laboratory report). Factory loaded ammunition employed a 510Gr soft point & a 500Gr round nosed THICK steel jacketed FMJ solid. When freshly manufactured ammunition was being used, all was good. But the ammunition was plagued with a short shelf life, due to the compressed charges of Winchester ball powder propellant inside the short 2.5” length cases. This would cause the powder propellant to clump and lead to partial ignition (which thusly led to predictably but abnormally unacceptable velocities). In the heat of humid African hunting terrain (such as the Zambezi valley or Rift valley or Kalahari desert), the short shelf life would become EVEN SHORTER. Quality control was also an issue. Winchester was manufacturing certain batches of .458 bullets which were undersized. And certain boxes of factory loaded Winchester cartridges had rounds which were loaded with both ball powder propellant and extruded powder propellant IN THE SAME BOX.

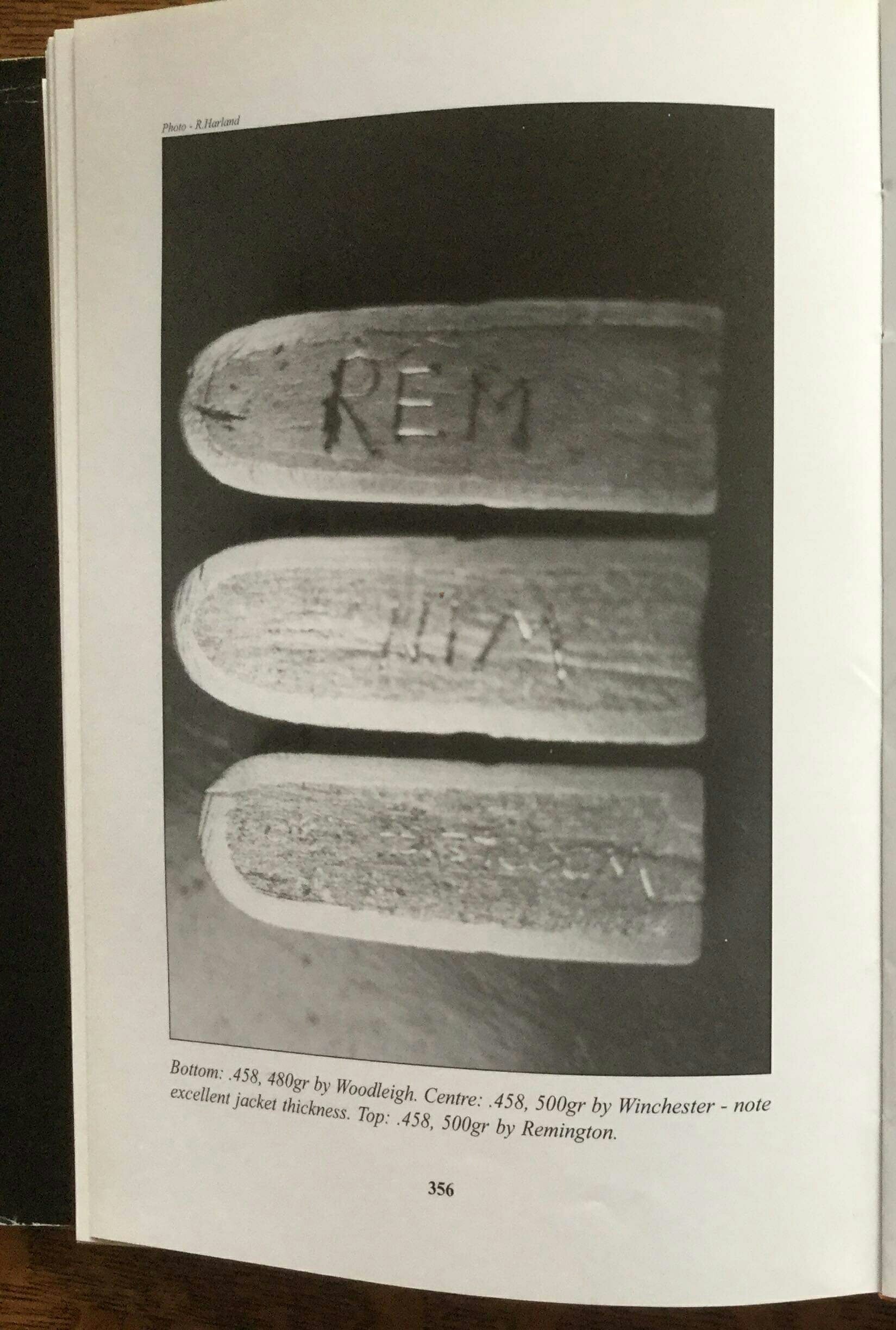

In 1961, Remington introduced their line of .458 Winchester Magnum ammunition. Velocities were advertised as 2130 fps (although the actual chronographed velocity was also 2087 fps when fired from the 25” barrel of a Winchester Model 70 as per an H.P White laboratory report). Factory loaded ammunition employed a 510Gr soft point & a 500Gr round nosed THIN steel jacketed FMJ solid. It was plagued by the same shelf life problems which the Winchester ammunition was suffering from. With 2 added disadvantages:

1) On account of the thin steel jackets, the Remington solids were noticeably more prone to distortion/bending/riveting/breaking apart than the Winchester solids.

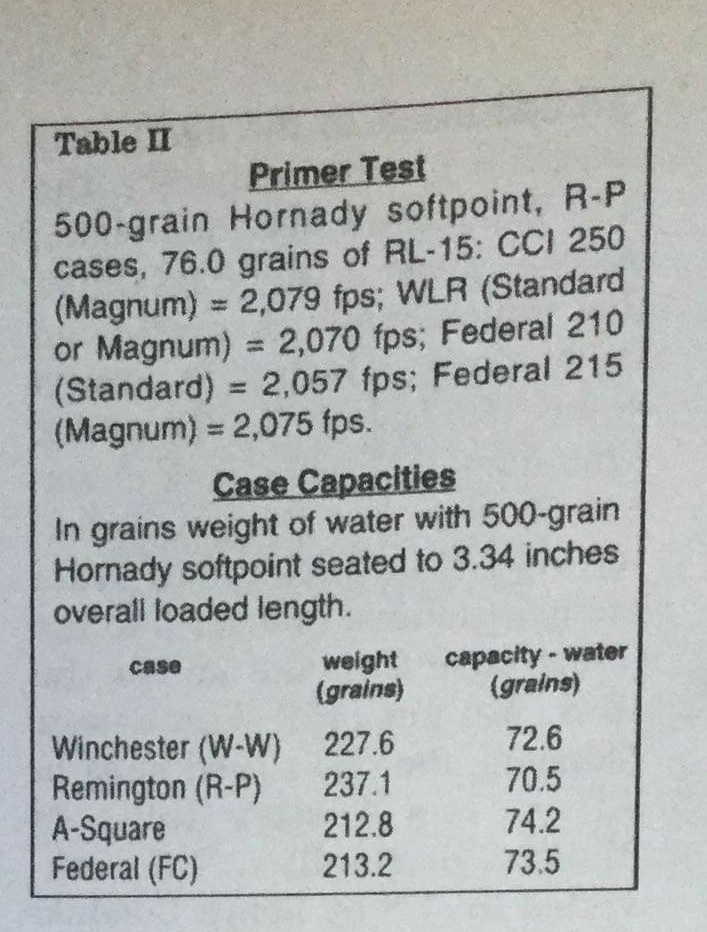

2) Remington cases had even less powder capacity in them compared to the Winchester cases. And thus, the ball powder propellant charges would be requiring slightly MORE compression.

But to Remington’s credit, their .458 Winchester Magnum ammunition did not suffer from the quality control problems that were prevalent in the Winchester ammunition.

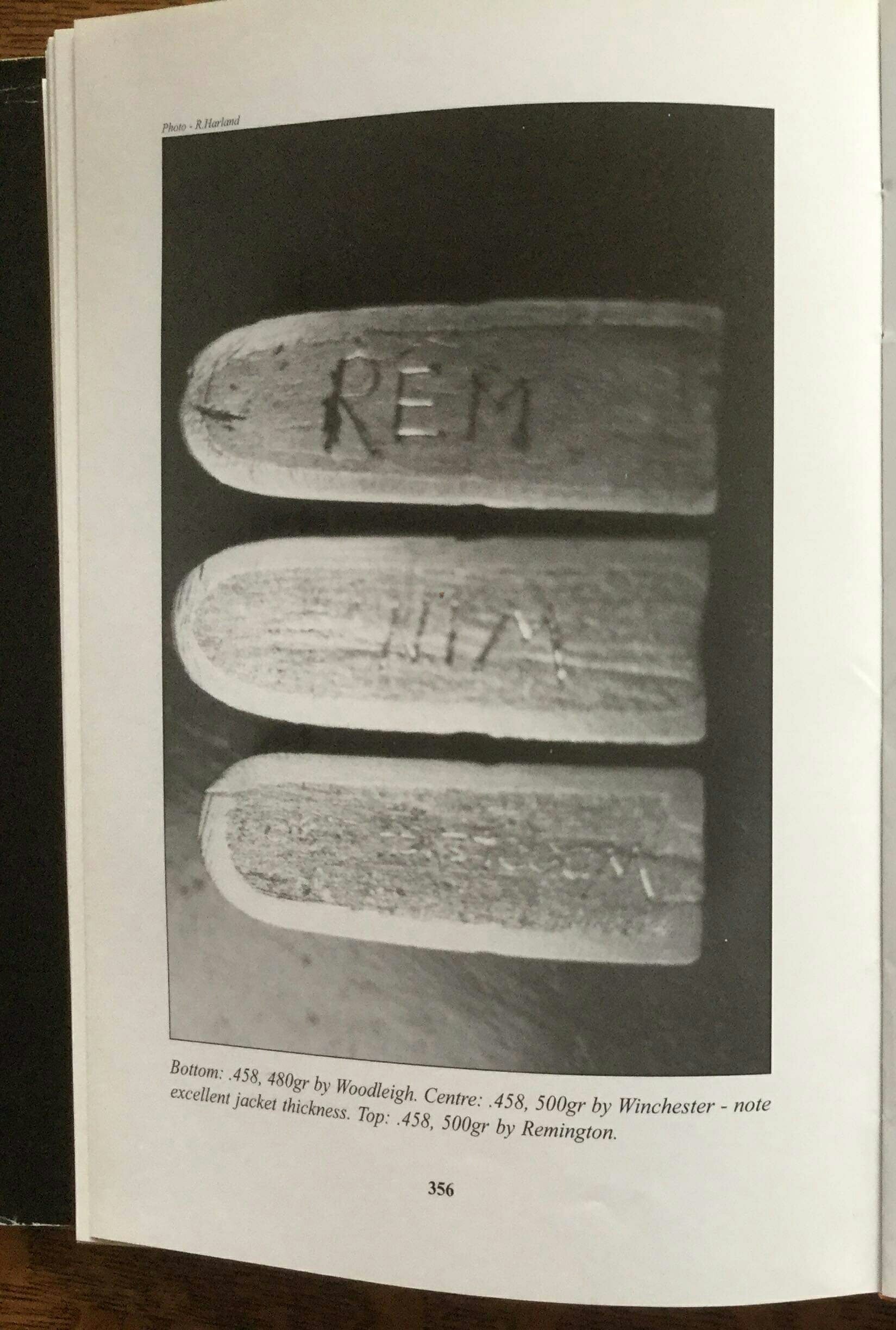

Sectioned .458 Winchester Magnum round nosed steel jacketed FMJ solid bullets manufactured by both Winchester & Remington (pre 1969). Observe the thickness of the Winchester steel jacket compared to the Remington steel jacket.

Photograph Source: “NDLOVU: The Art Of Hunting The African Elephant” by Richard Harland.

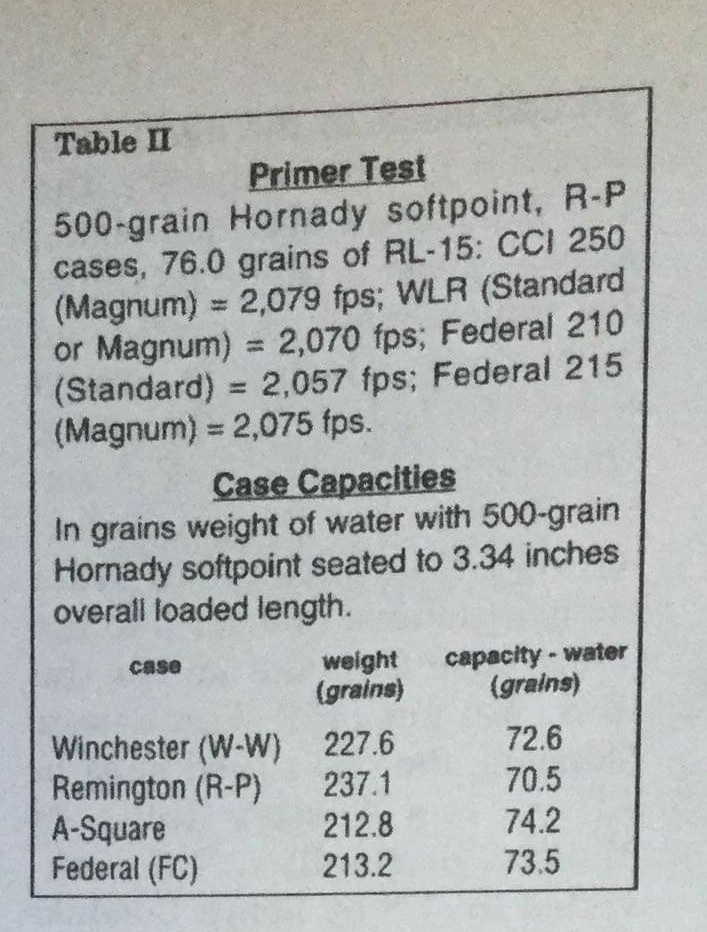

Comparison of powder capacity of different brands of .458 Winchester Magnum cartridge cases. Observe how Remington cases hold the least amount of water.

Photograph Source: Finn Aagaard Selected Works

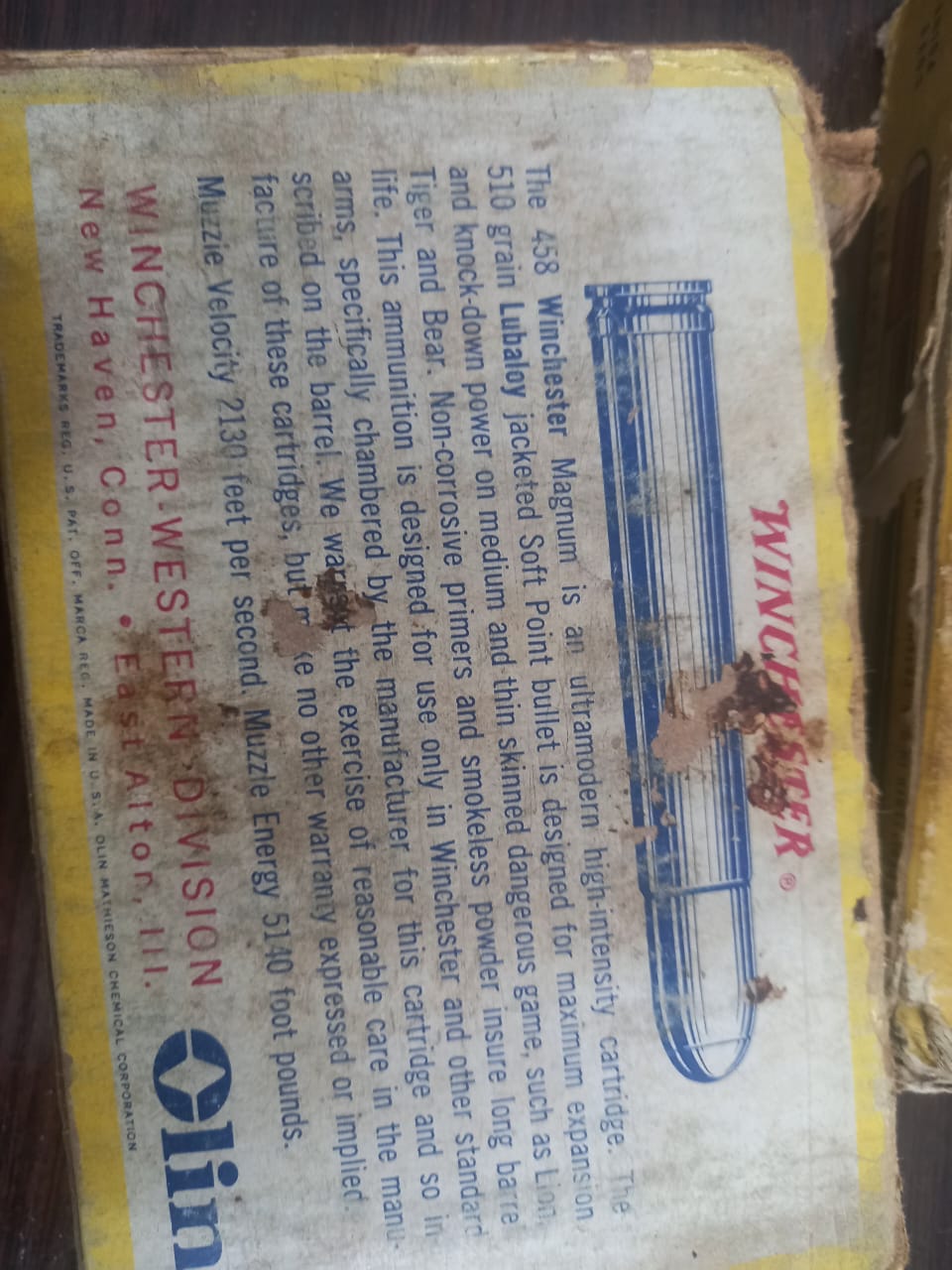

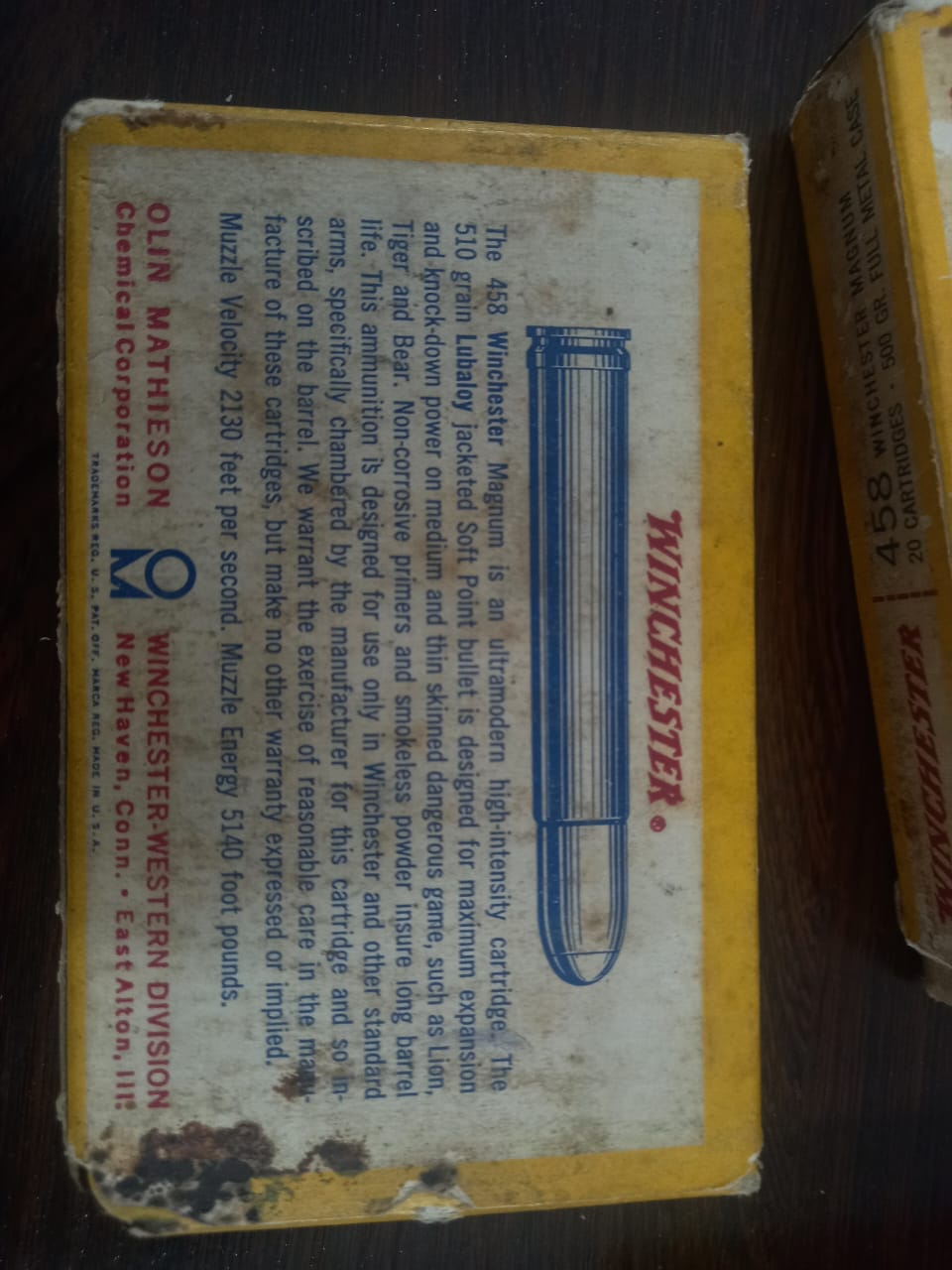

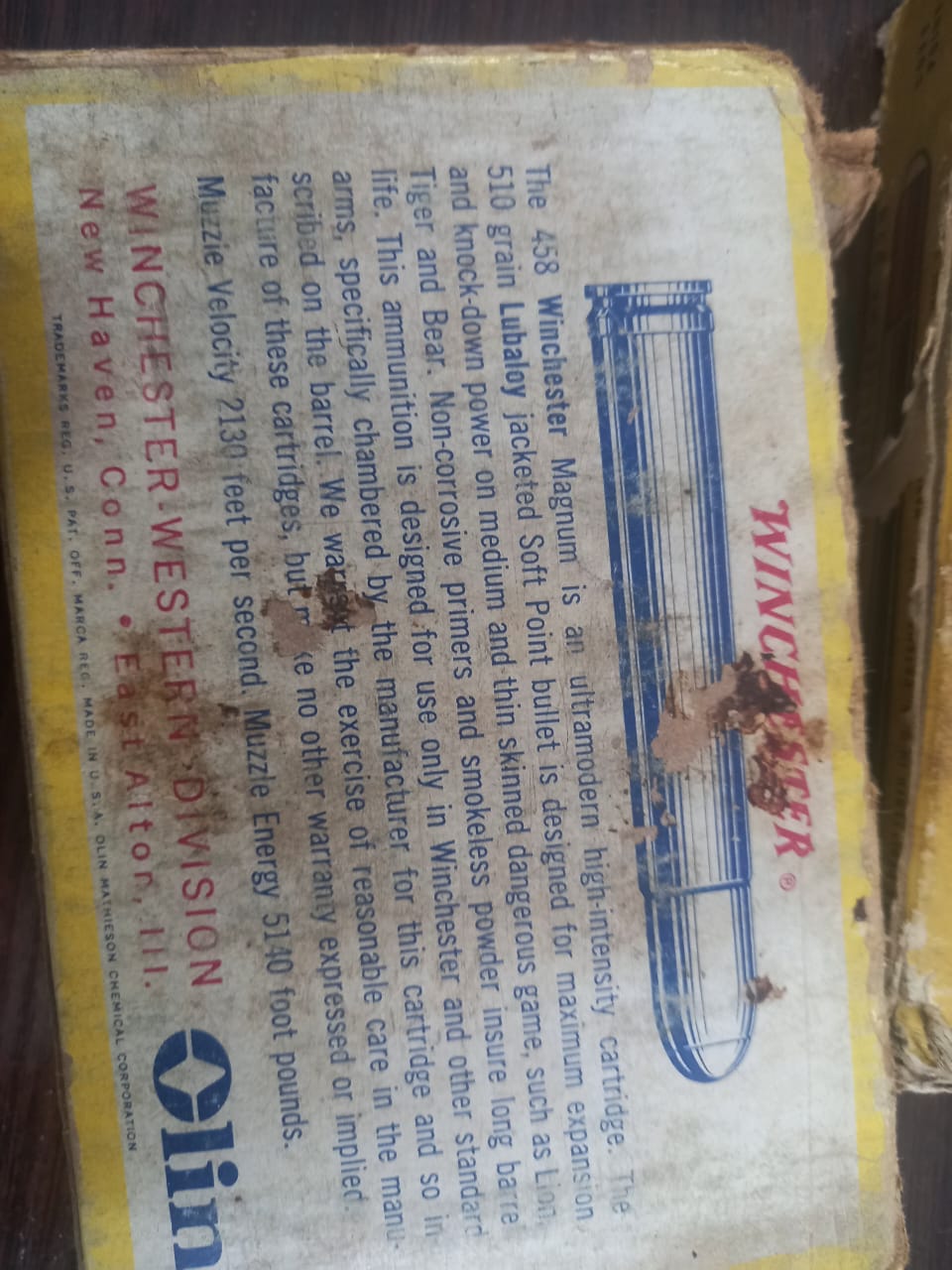

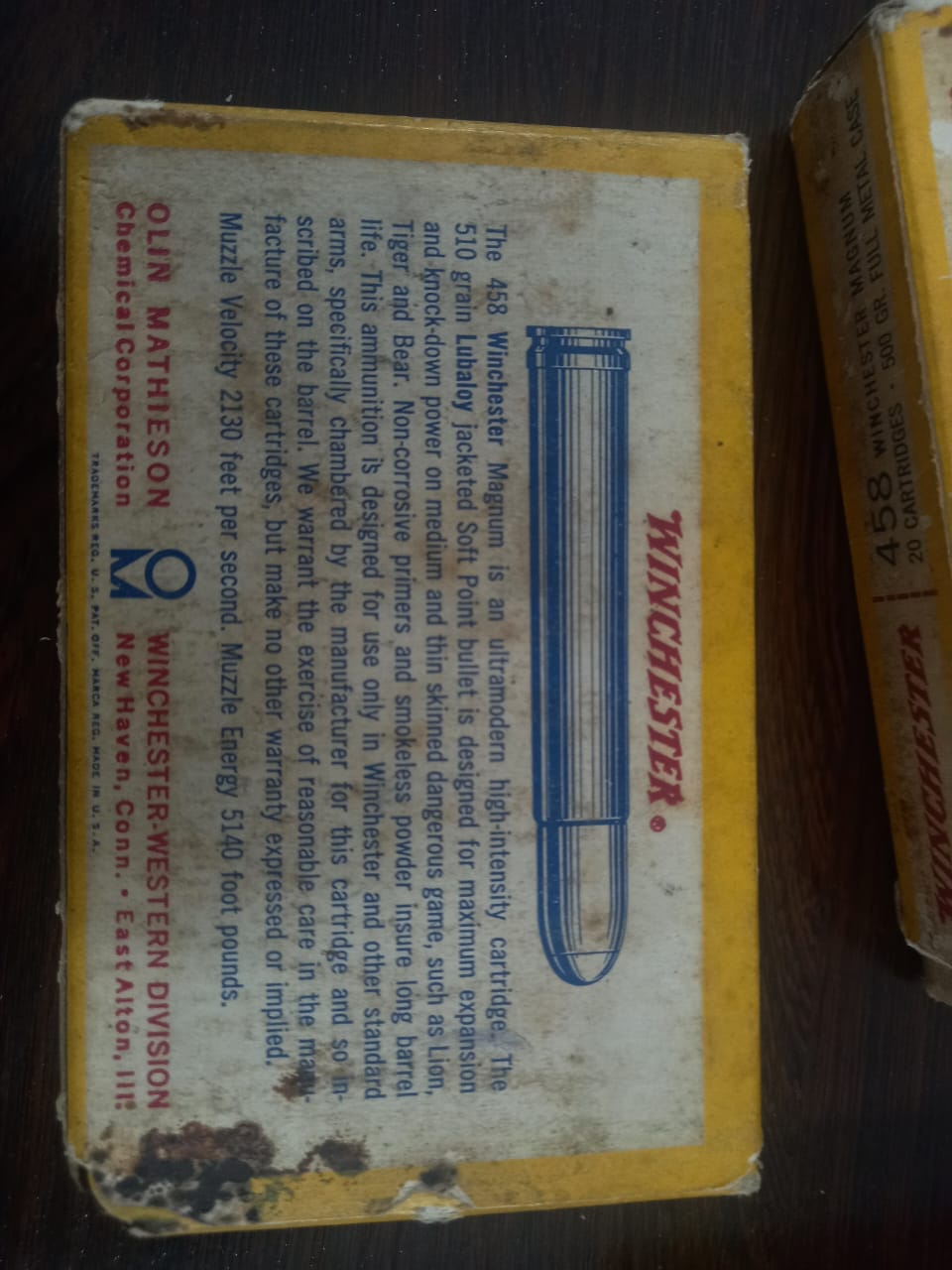

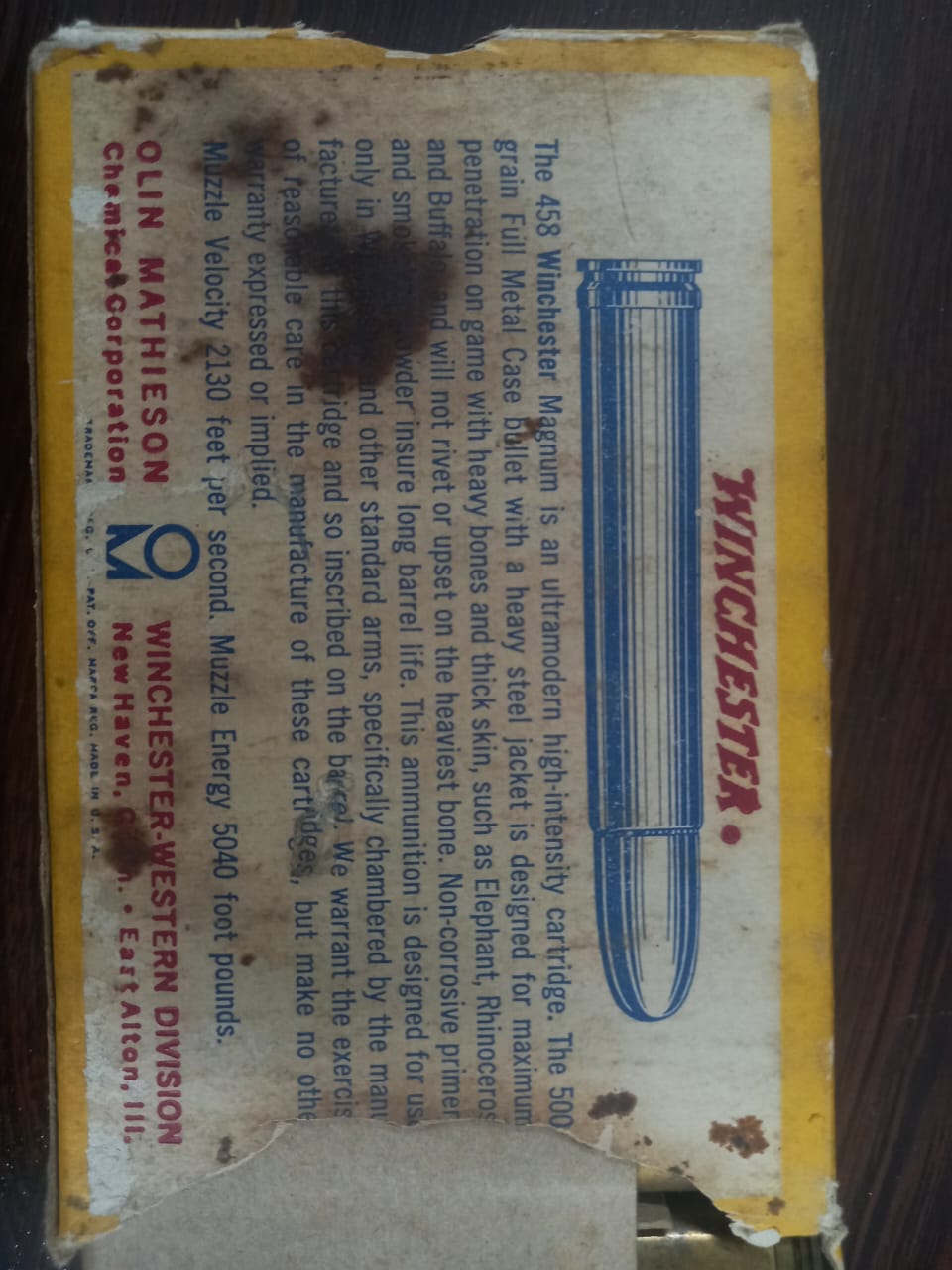

Here you can see vintage pre 1969 Winchester factory loaded ammunition for the .458 Winchester Magnum, owned by a friend.

Here are some of the cartridges from these boxes opened up. Observe the grotesque degree of clumping. My friend had to use a screwdriver in order to dislodge the clumped & compressed powder.

In 1969, Winchester (and subsequently Remington) did 2 things which had disastrous effects for the already problematic .458 Winchester Magnum:

1) They reduced the powder charge in an attempt to prevent the powder propellant from clumping up. Velocities were now advertised as 2040 fps, even though the chronographed velocities were now in the range of 1950 fps. But the shelf life problems were now solved.

2) In an attempt to reduce manufacturing costs, they replaced their proprietary steel jacketed .458 bullets with cupronickel jacketed .458 bullets that were being manufactured by Hornady.

The result was that all available factory loaded ammunition for the .458 Winchester Magnum was now underpowered and weakly constructed (becoming notorious for frequently failing to penetrate and/or breaking apart when being used against large dangerous game).

In 1982, Winchester and Remington both started using Hornady round nosed steel jacketed FMJ & soft point bullets in their .458 Winchester Magnum ammunition (Joyce Hornady sensibly decided to switch back to steel jackets during this time, for his solid bullets). Bullet quality improved, but the achievable velocities were still not high enough for reliably taking large bull elephants with frontal brain shots. Bullet quality deteriorated once again in 1995, when Hornady again reverted back to the “More economically viable” choice of cupronickel jackets for their solid bullets.

This continued up until Winchester and Remington both stopped manufacturing .458 Winchester Magnum ammunition in 1997. From 2006-2010, Winchester briefly manufactured ammunition for this caliber again, using 500Gr Nosler Partitions and 500Gr Nosler flat nosed monolithic solids (which were manufactured by Norma). Advertised velocities were 2100fps (and to their credit, chronographed velocities were a good 2085-2093 fps), but shelf life was quite low and Winchester eventually stopped loading for this caliber once again in 2010.

In 1993, Federal started loading ammunition for the .458 Winchester Magnum. Choices of bullets were either a 500Gr Trophy Bonded Bear Claw soft point or a 500Gr flat nosed brass jacketed Trophy Bonded Sledgehammer FMJ solid. Advertised velocities were 2150 fps. But shelf life problems emerged once again, this forcing Federal to reduce their powder charge. Current advertised velocity from Federal is 2090 fps for their Trophy Bonded Bear Claw loading and 1950 fps for their Trophy Bonded Sledgehammer loading. Occasional batches of poorly constructed Trophy Bonded Sledgehammer bullets from Speer (once Jack Carter ceased to be affiliated with Federal) have also been a problem for the Federal .458 Winchester Magnum ammuntion.

In 2000, Hornady designed a factory loading for the .458 Winchester Magnum which they termed as the “Heavy Magnum“ line. Bullet offerings comprised of a 500Gr round nosed steel jacketed FMJ solid & a 500Gr Interlock soft point.

Advertised velocity was 2150 fps, but shelf life was so short that Hornady themselves instructed purchasers of this ammunition to use the cartridges up within 6 months of fresh manufacture. The Hornady Heavy Magnum’s production life was quite short lived.

The modern Hornady Dangerous Game Series line of ammunition (introduced in 2006) appears to have finally solved the shelf life issues with the .458 Winchester Magnum. 500Gr flat nosed steel jacketed Dangerous Game Solids (DGS) and 500Gr Dangerous Game eXpanding (DGX) soft points are now advertised as being capable of achieving 2140 fps. Indeed, chronographed velocities are around 2134 fps even from boxes of ammunition that are more than 5 years old. But only time will tell if the shelf life problems have really been solved.

There are two solutions for making the .458 Winchester Magnum a very reliable dangerous game performer:

1) Drop bullet weight down to 450-475Gr in order to achieve increased powder capacity. Sectional density gets compromised a bit, but not unacceptably so. And velocity is improved without compromising shelf life.

2) Use 500Gr bullets but only in fresh hand loads with extruded powder propellant. Load your ammunition up just a few days prior to the hunt and store in a cool gun safe with little packets of silica gel, in order to keep out the moisture.

Indeed, the last factory loaded .458 Winchester Magnum offering from Remington employed a 450Gr Swift A Frame bullet. And today, 450Gr Barnes TSX hollow points & 450Gr Cutting Edge Bullets Safari Solids would be absolutely amazing for the .458 Winchester Magnum.

Retired Tanzanian game ranger and white hunter, the late Terry Irwin exclusively used his .458 Winchester Magnum Mannlicher Schoenauer (one of only 77 ever to be built) to take upwards of 1500 African elephants from 1964 to 1969 (when he shot his final elephant). His ammunition of choice consisted of fresh hand loads employing IMR3031 powder propellant and 500Gr Hornady round nosed steel jacketed FMJ solids (fortunately for him, Hornady was using steel jackets in their solid bullets until 1969). And 500Gr Hornady soft points for lions. The 26” barrel and short throat of his Mannlicher Schoenauer also greatly contributed to the good velocity which his hand loads were achieving (2097 fps). The notion of only using fresh hand loads in the .458 Winchester Magnum was also endorsed by Colonel Arthur Alphin (of A square) and the late Harry Selby.

For the elephant culling programs in Zimbabwe during the 1980s, Colonel Alphin was supplying the National Parks with large consignments of specially loaded .458 Winchester Magnum ammunition. 500Gr Hornady round nosed steel jacketed FMJ solids were loaded into Remington cases with IMR3031 powder propellant in order to achieve a chronographed velocity of 2128 fps. Shelf life was low (just as the Colonel had anticipated), but the ammunition was excellent when used fresh. The same applied for A Square’s commercially offered ammunition (which employed 465gr monolithic solid bullets). A consignment of this ammunition supplied to the National Parks in 1991, had the powder propellant in all of the cartridges get seriously clumped by 2000.

Richard Harland (very deservedly so) gained good reputation for successfully using the .458 Winchester Magnum against thousands of African elephants in the Rhodesian corridors during his elephant control duties up until 1968. He was using a game department issued Mannlicher Schoenauer in this caliber (identical to Terry Irwin’s rifle) and ONlY used FRESH consignments of Winchester factory loaded 500Gr round nosed steel jacketed FMJ solids. He did not hand load for the .458 Winchester Magnum until 2007 (when he developed duplex load for this caliber by using 475Gr DZOMBO flat nosed brass monolithic solids and 2 kinds of Somchem powder). But he used these hand loads very few times as he retired from dangerous game hunting shortly afterwards. He personally owned 2 rifles in .458 Winchester Magnum: A BSA Majestic (which was gifted to him by the late Paul Grobler) and a Flaig’s FN Mauser action custom piece (which American client Zachary Miller originally had custom built for himself but gifted to Richard after a safari in 1973).

In conclusion, If you are buying a brand new dangerous game rifle… then, there are several better options available on the modern market than a .458 Winchester Magnum. But if a .458 Winchester Magnum is easily available to you and/or you already own one, the there’s absolutely no need to feel discouraged and discard it.

When I went on my life’s first African Safari to Kenya in 1974, I noticed that the game department law stipulated a minimum bore size of .400 caliber for hunting elephant & rhinoceros & Cape buffalo & hippopotamus. Due to Kynoch completely ceasing manufacture of centerfire ammunition in 1970, there were no commercially available cartridges for the traditional British large bore rifles of .400 caliber or above (since Kynoch was the only firm to ever manufacture any ammunition for them back in those days). And hand loading was illegal in Kenya. So basically, the .458 Winchester Magnum was the only caliber for which commercially manufactured .400+ caliber ammunition was available in Kenya (only Winchester since no gun shops in Kenya ever imported any Remington brand ammunition).

My white hunter, Mr, Cheffings considerately & discreetly permitted me to take my Cape buffalo (my life’s first one) with a .375 Holland & Holland Magnum (a BRNO ZKK-602 loaded with 1 RWS Kegelspitze 300Gr soft point & 5 RWS round nosed steel jacketed 300Gr FMJ solids). And I developed an immense life long respect for the .375 Holland & Holland Magnum immediately.

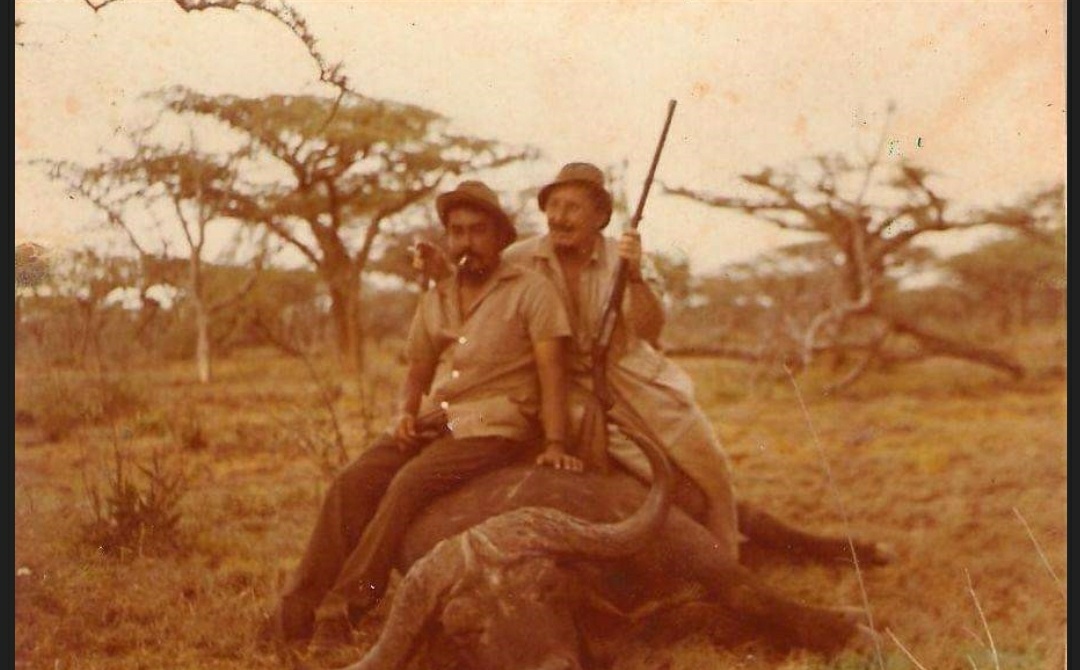

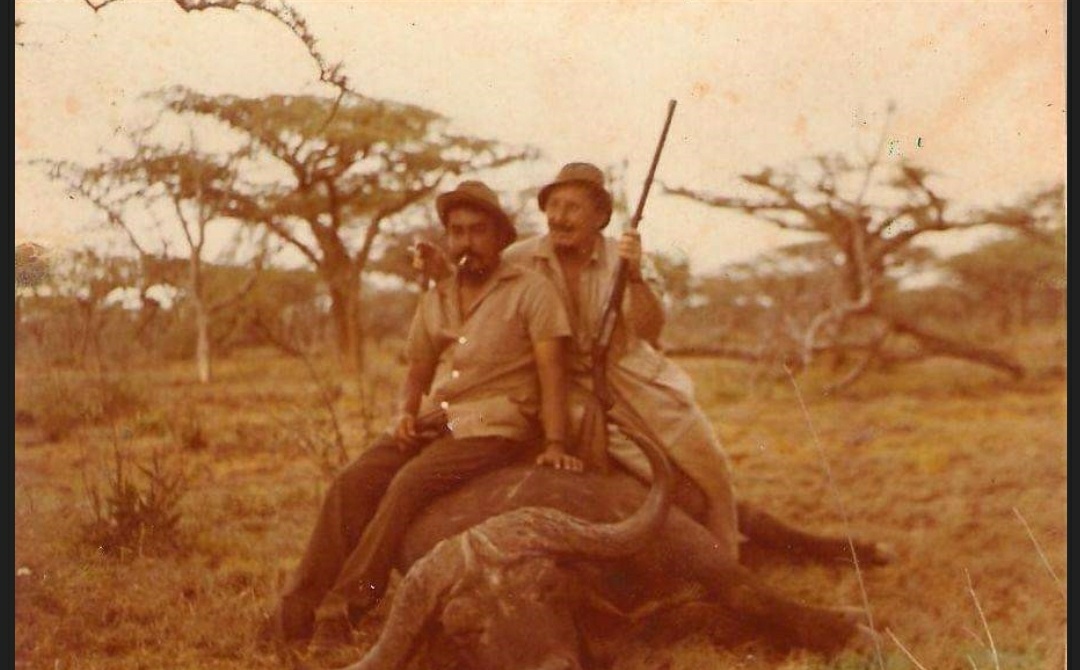

But I did later use a .458 Winchester Magnum to take this Cape buffalo on my 3rd African Safari (to Tanzania). It was a Belgium made boxlock ejector double rifle (a “Guild Gun”) and the ammunition comprised of hand loaded 500Gr Hornady soft points and round nosed steel jacketed FMJ solids. The fresh hand loads served me extremely well, and the Cape buffalo eventually folded after the first 2 shots. Although the rifle’s ejectors did fail to extract the expended cartridge cases from the breech after my 2 shots.

When Winchester introduced their .458 Winchester Magnum caliber in 1956, velocities were advertised as 2130 fps (although the actual chronographed velocity was 2087 fps when fired from the 25” barrel of a Winchester Model 70 as per an H.P White laboratory report). Factory loaded ammunition employed a 510Gr soft point & a 500Gr round nosed THICK steel jacketed FMJ solid. When freshly manufactured ammunition was being used, all was good. But the ammunition was plagued with a short shelf life, due to the compressed charges of Winchester ball powder propellant inside the short 2.5” length cases. This would cause the powder propellant to clump and lead to partial ignition (which thusly led to predictably but abnormally unacceptable velocities). In the heat of humid African hunting terrain (such as the Zambezi valley or Rift valley or Kalahari desert), the short shelf life would become EVEN SHORTER. Quality control was also an issue. Winchester was manufacturing certain batches of .458 bullets which were undersized. And certain boxes of factory loaded Winchester cartridges had rounds which were loaded with both ball powder propellant and extruded powder propellant IN THE SAME BOX.

In 1961, Remington introduced their line of .458 Winchester Magnum ammunition. Velocities were advertised as 2130 fps (although the actual chronographed velocity was also 2087 fps when fired from the 25” barrel of a Winchester Model 70 as per an H.P White laboratory report). Factory loaded ammunition employed a 510Gr soft point & a 500Gr round nosed THIN steel jacketed FMJ solid. It was plagued by the same shelf life problems which the Winchester ammunition was suffering from. With 2 added disadvantages:

1) On account of the thin steel jackets, the Remington solids were noticeably more prone to distortion/bending/riveting/breaking apart than the Winchester solids.

2) Remington cases had even less powder capacity in them compared to the Winchester cases. And thus, the ball powder propellant charges would be requiring slightly MORE compression.

But to Remington’s credit, their .458 Winchester Magnum ammunition did not suffer from the quality control problems that were prevalent in the Winchester ammunition.

Sectioned .458 Winchester Magnum round nosed steel jacketed FMJ solid bullets manufactured by both Winchester & Remington (pre 1969). Observe the thickness of the Winchester steel jacket compared to the Remington steel jacket.

Photograph Source: “NDLOVU: The Art Of Hunting The African Elephant” by Richard Harland.

Comparison of powder capacity of different brands of .458 Winchester Magnum cartridge cases. Observe how Remington cases hold the least amount of water.

Photograph Source: Finn Aagaard Selected Works

Here you can see vintage pre 1969 Winchester factory loaded ammunition for the .458 Winchester Magnum, owned by a friend.

Here are some of the cartridges from these boxes opened up. Observe the grotesque degree of clumping. My friend had to use a screwdriver in order to dislodge the clumped & compressed powder.

In 1969, Winchester (and subsequently Remington) did 2 things which had disastrous effects for the already problematic .458 Winchester Magnum:

1) They reduced the powder charge in an attempt to prevent the powder propellant from clumping up. Velocities were now advertised as 2040 fps, even though the chronographed velocities were now in the range of 1950 fps. But the shelf life problems were now solved.

2) In an attempt to reduce manufacturing costs, they replaced their proprietary steel jacketed .458 bullets with cupronickel jacketed .458 bullets that were being manufactured by Hornady.

The result was that all available factory loaded ammunition for the .458 Winchester Magnum was now underpowered and weakly constructed (becoming notorious for frequently failing to penetrate and/or breaking apart when being used against large dangerous game).

In 1982, Winchester and Remington both started using Hornady round nosed steel jacketed FMJ & soft point bullets in their .458 Winchester Magnum ammunition (Joyce Hornady sensibly decided to switch back to steel jackets during this time, for his solid bullets). Bullet quality improved, but the achievable velocities were still not high enough for reliably taking large bull elephants with frontal brain shots. Bullet quality deteriorated once again in 1995, when Hornady again reverted back to the “More economically viable” choice of cupronickel jackets for their solid bullets.

This continued up until Winchester and Remington both stopped manufacturing .458 Winchester Magnum ammunition in 1997. From 2006-2010, Winchester briefly manufactured ammunition for this caliber again, using 500Gr Nosler Partitions and 500Gr Nosler flat nosed monolithic solids (which were manufactured by Norma). Advertised velocities were 2100fps (and to their credit, chronographed velocities were a good 2085-2093 fps), but shelf life was quite low and Winchester eventually stopped loading for this caliber once again in 2010.

In 1993, Federal started loading ammunition for the .458 Winchester Magnum. Choices of bullets were either a 500Gr Trophy Bonded Bear Claw soft point or a 500Gr flat nosed brass jacketed Trophy Bonded Sledgehammer FMJ solid. Advertised velocities were 2150 fps. But shelf life problems emerged once again, this forcing Federal to reduce their powder charge. Current advertised velocity from Federal is 2090 fps for their Trophy Bonded Bear Claw loading and 1950 fps for their Trophy Bonded Sledgehammer loading. Occasional batches of poorly constructed Trophy Bonded Sledgehammer bullets from Speer (once Jack Carter ceased to be affiliated with Federal) have also been a problem for the Federal .458 Winchester Magnum ammuntion.

In 2000, Hornady designed a factory loading for the .458 Winchester Magnum which they termed as the “Heavy Magnum“ line. Bullet offerings comprised of a 500Gr round nosed steel jacketed FMJ solid & a 500Gr Interlock soft point.

Advertised velocity was 2150 fps, but shelf life was so short that Hornady themselves instructed purchasers of this ammunition to use the cartridges up within 6 months of fresh manufacture. The Hornady Heavy Magnum’s production life was quite short lived.

The modern Hornady Dangerous Game Series line of ammunition (introduced in 2006) appears to have finally solved the shelf life issues with the .458 Winchester Magnum. 500Gr flat nosed steel jacketed Dangerous Game Solids (DGS) and 500Gr Dangerous Game eXpanding (DGX) soft points are now advertised as being capable of achieving 2140 fps. Indeed, chronographed velocities are around 2134 fps even from boxes of ammunition that are more than 5 years old. But only time will tell if the shelf life problems have really been solved.

There are two solutions for making the .458 Winchester Magnum a very reliable dangerous game performer:

1) Drop bullet weight down to 450-475Gr in order to achieve increased powder capacity. Sectional density gets compromised a bit, but not unacceptably so. And velocity is improved without compromising shelf life.

2) Use 500Gr bullets but only in fresh hand loads with extruded powder propellant. Load your ammunition up just a few days prior to the hunt and store in a cool gun safe with little packets of silica gel, in order to keep out the moisture.

Indeed, the last factory loaded .458 Winchester Magnum offering from Remington employed a 450Gr Swift A Frame bullet. And today, 450Gr Barnes TSX hollow points & 450Gr Cutting Edge Bullets Safari Solids would be absolutely amazing for the .458 Winchester Magnum.

Retired Tanzanian game ranger and white hunter, the late Terry Irwin exclusively used his .458 Winchester Magnum Mannlicher Schoenauer (one of only 77 ever to be built) to take upwards of 1500 African elephants from 1964 to 1969 (when he shot his final elephant). His ammunition of choice consisted of fresh hand loads employing IMR3031 powder propellant and 500Gr Hornady round nosed steel jacketed FMJ solids (fortunately for him, Hornady was using steel jackets in their solid bullets until 1969). And 500Gr Hornady soft points for lions. The 26” barrel and short throat of his Mannlicher Schoenauer also greatly contributed to the good velocity which his hand loads were achieving (2097 fps). The notion of only using fresh hand loads in the .458 Winchester Magnum was also endorsed by Colonel Arthur Alphin (of A square) and the late Harry Selby.

For the elephant culling programs in Zimbabwe during the 1980s, Colonel Alphin was supplying the National Parks with large consignments of specially loaded .458 Winchester Magnum ammunition. 500Gr Hornady round nosed steel jacketed FMJ solids were loaded into Remington cases with IMR3031 powder propellant in order to achieve a chronographed velocity of 2128 fps. Shelf life was low (just as the Colonel had anticipated), but the ammunition was excellent when used fresh. The same applied for A Square’s commercially offered ammunition (which employed 465gr monolithic solid bullets). A consignment of this ammunition supplied to the National Parks in 1991, had the powder propellant in all of the cartridges get seriously clumped by 2000.

Richard Harland (very deservedly so) gained good reputation for successfully using the .458 Winchester Magnum against thousands of African elephants in the Rhodesian corridors during his elephant control duties up until 1968. He was using a game department issued Mannlicher Schoenauer in this caliber (identical to Terry Irwin’s rifle) and ONlY used FRESH consignments of Winchester factory loaded 500Gr round nosed steel jacketed FMJ solids. He did not hand load for the .458 Winchester Magnum until 2007 (when he developed duplex load for this caliber by using 475Gr DZOMBO flat nosed brass monolithic solids and 2 kinds of Somchem powder). But he used these hand loads very few times as he retired from dangerous game hunting shortly afterwards. He personally owned 2 rifles in .458 Winchester Magnum: A BSA Majestic (which was gifted to him by the late Paul Grobler) and a Flaig’s FN Mauser action custom piece (which American client Zachary Miller originally had custom built for himself but gifted to Richard after a safari in 1973).

In conclusion, If you are buying a brand new dangerous game rifle… then, there are several better options available on the modern market than a .458 Winchester Magnum. But if a .458 Winchester Magnum is easily available to you and/or you already own one, the there’s absolutely no need to feel discouraged and discard it.

When I went on my life’s first African Safari to Kenya in 1974, I noticed that the game department law stipulated a minimum bore size of .400 caliber for hunting elephant & rhinoceros & Cape buffalo & hippopotamus. Due to Kynoch completely ceasing manufacture of centerfire ammunition in 1970, there were no commercially available cartridges for the traditional British large bore rifles of .400 caliber or above (since Kynoch was the only firm to ever manufacture any ammunition for them back in those days). And hand loading was illegal in Kenya. So basically, the .458 Winchester Magnum was the only caliber for which commercially manufactured .400+ caliber ammunition was available in Kenya (only Winchester since no gun shops in Kenya ever imported any Remington brand ammunition).

My white hunter, Mr, Cheffings considerately & discreetly permitted me to take my Cape buffalo (my life’s first one) with a .375 Holland & Holland Magnum (a BRNO ZKK-602 loaded with 1 RWS Kegelspitze 300Gr soft point & 5 RWS round nosed steel jacketed 300Gr FMJ solids). And I developed an immense life long respect for the .375 Holland & Holland Magnum immediately.

But I did later use a .458 Winchester Magnum to take this Cape buffalo on my 3rd African Safari (to Tanzania). It was a Belgium made boxlock ejector double rifle (a “Guild Gun”) and the ammunition comprised of hand loaded 500Gr Hornady soft points and round nosed steel jacketed FMJ solids. The fresh hand loads served me extremely well, and the Cape buffalo eventually folded after the first 2 shots. Although the rifle’s ejectors did fail to extract the expended cartridge cases from the breech after my 2 shots.

Last edited:

Nhoro

AH elite

- Joined

- Sep 16, 2014

- Messages

- 1,037

- Reaction score

- 1,997

- Location

- Harare,Zimbabwe

- Media

- 29

- Member of

- Cleveland Gun Club

- Hunted

- Zimbabwe

I have a CZ 550 in 458 win mag and used 480 gr Hornady and 450 gr Peregrine (mono copper). I was able to get 2250 fps with Somchem powder. They slightly lighter bullets help with powder space and still have sectional density to equal the 300 gr 375 bullet. My rifle went in for some work on the sights and the smith offered a free reaming to Lott. I still carried the Win mag ammo until I finished it. Hornady ammo makes the velocity on the box with 500 gr. Handloads, I think 450 gr monos and 480 gr hornady bullets are in the sweet spot.

I load 458 Winchester to regulate in my Heym 88B. My loads for same Poinf of Impact are:

I have pushed the 470 gr CEBs to 2200 fps but Mr. Heym objected to them as evidenced in the wide dispersion between left and right barrels' POI.

Buffalo cow shot with .458 Heym 88B. Stalk didn't go as planned, opportunity at 100m. Dead buff!

470 Cutting Edge Bullet Safari Raptor at 2150 fps.

Lioness in Kalahari wiht same 470 Safari Raptor shot at appoximately 45m

Wild-e-beast shot at 150m with same 458 Heym and 470 Safari Raptor. Only opportunity was at dusk at extended range for double rifle and mighty four-five-eight!

I load with Hodgdon H4895 with un-compressed powder charges. That powder is hard to find but with badger-like persistance, one can find enough.

Not big critters for a 458 but when in Africa...

Wife posing with giraffe downed by 458 Win.

My elephant didn't happen in 2021 but my trusty Heym 458 will and I will have another go at them next year!

- 500 gr Cutting Edge Bullets Safari Solid at 2150

- 470 gr CEB Safari Raptor at 2150

I have pushed the 470 gr CEBs to 2200 fps but Mr. Heym objected to them as evidenced in the wide dispersion between left and right barrels' POI.

Buffalo cow shot with .458 Heym 88B. Stalk didn't go as planned, opportunity at 100m. Dead buff!

470 Cutting Edge Bullet Safari Raptor at 2150 fps.

Lioness in Kalahari wiht same 470 Safari Raptor shot at appoximately 45m

Wild-e-beast shot at 150m with same 458 Heym and 470 Safari Raptor. Only opportunity was at dusk at extended range for double rifle and mighty four-five-eight!

I load with Hodgdon H4895 with un-compressed powder charges. That powder is hard to find but with badger-like persistance, one can find enough.

Not big critters for a 458 but when in Africa...

Wife posing with giraffe downed by 458 Win.

My elephant didn't happen in 2021 but my trusty Heym 458 will and I will have another go at them next year!

enysse

AH ambassador

- Joined

- Jan 20, 2009

- Messages

- 12,214

- Reaction score

- 4,752

- Media

- 136

- Member of

- Northeast Wisconsin SCI chapter, Lifetime member of NRA,RMEF

- Hunted

- Namibia, South Africa (East Cape, Guateng and Limpopo)

With modern gun powder and bullets you will have no problems. Back in the day when they introduced the caliber they were using powder and bullets prone to having potentially problems.

flying sailor

AH fanatic

Thank-you for the terrific write up. I own a .458 WM and certainly feel better. I hand load and knew there would be updated info for those who like the cartridge.The answer to this question needs very careful historical and ballistic assessment.

When Winchester introduced their .458 Winchester Magnum caliber in 1956, velocities were advertised as 2130 fps (although the actual chronographed velocity was 2087 fps when fired from the 25” barrel of a Winchester Model 70 as per an H.P White laboratory report). Factory loaded ammunition employed a 510Gr soft point & a 500Gr round nosed THICK steel jacketed FMJ solid. When freshly manufactured ammunition was being used, all was good. But the ammunition was plagued with a short shelf life, due to the compressed charges of Winchester ball powder propellant inside the short 2.5” length cases. This would cause the powder propellant to clump and lead to partial ignition (which thusly led to predictably but abnormally unacceptable velocities). In the heat of humid African hunting terrain (such as the Zambezi valley or Rift valley or Kalahari desert), the short shelf life would become EVEN SHORTER. Quality control was also an issue. Winchester was manufacturing certain batches of .458 bullets which were undersized. And certain boxes of factory loaded Winchester cartridges had rounds which were loaded with both ball powder propellant and extruded powder propellant IN THE SAME BOX.

In 1961, Remington introduced their line of .458 Winchester Magnum ammunition. Velocities were advertised as 2130 fps (although the actual chronographed velocity was also 2087 fps when fired from the 25” barrel of a Winchester Model 70 as per an H.P White laboratory report). Factory loaded ammunition employed a 510Gr soft point & a 500Gr round nosed THIN steel jacketed FMJ solid. It was plagued by the same shelf life problems which the Winchester ammunition was suffering from. With 2 added disadvantages:

1) On account of the thin steel jackets, the Remington solids were noticeably more prone to distortion/bending/riveting/breaking apart than the Winchester solids.

2) Remington cases had even less powder capacity in them compared to the Winchester cases. And thus, the ball powder propellant charges would be requiring slightly MORE compression.

But to Remington’s credit, their .458 Winchester Magnum ammunition did not suffer from the quality control problems that were prevalent in the Winchester ammunition.

Sectioned .458 Winchester Magnum round nosed steel jacketed FMJ solid bullets manufactured by both Winchester & Remington (pre 1969). Observe the thickness of the Winchester steel jacket compared to the Remington steel jacket.

Photograph Source: “NDLOVU: The Art Of Hunting The African Elephant” by Richard Harland.

Comparison of powder capacity of different brands of .458 Winchester Magnum cartridge cases. Observe how Remington cases hold the least amount of water.

Photograph Source: Finn Aagaard Selected Works

Here you can see vintage pre 1969 Winchester factory loaded ammunition for the .458 Winchester Magnum, owned by a friend.

Here are some of the cartridges from these boxes opened up. Observe the grotesque degree of clumping. My friend had to use a screwdriver in order to dislodge the clumped & compressed powder.

In 1969, Winchester (and subsequently Remington) did 2 things which had disastrous effects for the already problematic .458 Winchester Magnum:

1) They reduced the powder charge in an attempt to prevent the powder propellant from clumping up. Velocities were now advertised as 2040 fps, even though the chronographed velocities were now in the range of 1950 fps. But the shelf life problems were now solved.

2) In an attempt to reduce manufacturing costs, they replaced their proprietary steel jacketed .458 bullets with cupronickel jacketed .458 bullets that were being manufactured by Hornady.

The result was that all available factory loaded ammunition for the .458 Winchester Magnum was now underpowered and weakly constructed (becoming notorious for frequently failing to penetrate and/or breaking apart when being used against large dangerous game).

In 1982, Winchester and Remington both started using Hornady round nosed steel jacketed FMJ & soft point bullets in their .458 Winchester Magnum ammunition (Joyce Hornady sensibly decided to switch back to steel jackets during this time, for his solid bullets). Bullet quality improved, but the achievable velocities were still not high enough for reliably taking large bull elephants with frontal brain shots. Bullet quality deteriorated once again in 1995, when Hornady again reverted back to the “More economically viable” choice of cupronickel jackets for their solid bullets.

This continued up until Winchester and Remington both stopped manufacturing .458 Winchester Magnum ammunition in 1997. From 2006-2010, Winchester briefly manufactured ammunition for this caliber again, using 500Gr Nosler Partitions and 500Gr Nosler flat nosed monolithic solids (which were manufactured by Norma). Advertised velocities were 2100fps (and to their credit, chronographed velocities were a good 2085-2093 fps), but shelf life was quite low and Winchester eventually stopped loading for this caliber once again in 2010.

In 1993, Federal started loading ammunition for the .458 Winchester Magnum. Choices of bullets were either a 500Gr Trophy Bonded Bear Claw soft point or a 500Gr flat nosed brass jacketed Trophy Bonded Sledgehammer FMJ solid. Advertised velocities were 2150 fps. But shelf life problems emerged once again, this forcing Federal to reduce their powder charge. Current advertised velocity from Federal is 2090 fps for their Trophy Bonded Bear Claw loading and 1950 fps for their Trophy Bonded Sledgehammer loading. Occasional batches of poorly constructed Trophy Bonded Sledgehammer bullets from Speer (once Jack Carter ceased to be affiliated with Federal) have also been a problem for the Federal .458 Winchester Magnum ammuntion.

In 2000, Hornady designed a factory loading for the .458 Winchester Magnum which they termed as the “Heavy Magnum“ line. Bullet offerings comprised of a 500Gr round nosed steel jacketed FMJ solid & a 500Gr Interlock soft point.

Advertised velocity was 2150 fps, but shelf life was so short that Hornady themselves instructed purchasers of this ammunition to use the cartridges up within 6 months of fresh manufacture. The Hornady Heavy Magnum’s production life was quite short lived.

The modern Hornady Dangerous Game Series line of ammunition (introduced in 2006) appears to have finally solved the shelf life issues with the .458 Winchester Magnum. 500Gr flat nosed steel jacketed Dangerous Game Solids (DGS) and 500Gr Dangerous Game eXpanding (DGX) soft points are now advertised as being capable of achieving 2140 fps. Indeed, chronographed velocities are around 2134 fps even from boxes of ammunition that are more than 5 years old. But only time will tell if the shelf life problems have really been solved.

There are two solutions for making the .458 Winchester Magnum a very reliable dangerous game performer:

1) Drop bullet weight down to 450-475Gr in order to achieve increased powder capacity. Sectional density gets compromised a bit, but not unacceptably so. And velocity is improved without compromising shelf life.

2) Use 500Gr bullets but only in fresh hand loads with extruded powder propellant. Load your ammunition up just a few days prior to the hunt and store in a cool gun safe with little packets of silica gel, in order to keep out the moisture.

Indeed, the last factory loaded .458 Winchester Magnum offering from Remington employed a 450Gr Swift A Frame bullet. And today, 450Gr Barnes TSX hollow points & 450Gr Cutting Edge Bullets Safari Solids would be absolutely amazing for the .458 Winchester Magnum.

Retired Tanzanian game ranger and white hunter, the late Terry Irwin exclusively used his .458 Winchester Magnum Mannlicher Schoenauer (one of only 77 ever to be built) to take upwards of 1500 African elephants from 1964 to 1969 (when he shot his final elephant). His ammunition of choice consisted of fresh hand loads employing IMR3031 powder propellant and 500Gr Hornady round nosed steel jacketed FMJ solids (fortunately for him, Hornady was using steel jackets in their solid bullets until 1969). And 500Gr Hornady soft points for lions. The 26” barrel and short throat of his Mannlicher Schoenauer also greatly contributed to the good velocity which his hand loads were achieving (2097 fps). The notion of only using fresh hand loads in the .458 Winchester Magnum was also endorsed by Colonel Arthur Alphin (of A square) and the late Harry Selby.

For the elephant culling programs in Zimbabwe during the 1980s, Colonel Alphin was supplying the National Parks with large consignments of specially loaded .458 Winchester Magnum ammunition. 500Gr Hornady round nosed steel jacketed FMJ solids were loaded into Remington cases with IMR3031 powder propellant in order to achieve a chronographed velocity of 2128 fps. Shelf life was low (just as the Colonel had anticipated), but the ammunition was excellent when used fresh. The same applied for A Square’s commercially offered ammunition (which employed 465gr monolithic solid bullets). A consignment of this ammunition supplied to the National Parks in 1991, had the powder propellant in all of the cartridges get seriously clumped by 2000.

Richard Harland (very deservedly so) gained good reputation for successfully using the .458 Winchester Magnum against thousands of African elephants in the Rhodesian corridors during his elephant control duties up until 1968. He was using a game department issued Mannlicher Schoenauer in this caliber (identical to Terry Irwin’s rifle) and ONlY used FRESH consignments of Winchester factory loaded 500Gr round nosed steel jacketed FMJ solids. He did not hand load for the .458 Winchester Magnum until 2007 (when he developed duplex load for this caliber by using 475Gr DZOMBO flat nosed brass monolithic solids and 2 kinds of Somchem powder). But he used these hand loads very few times as he retired from dangerous game hunting shortly afterwards. He personally owned 2 rifles in .458 Winchester Magnum: A BSA Majestic (which was gifted to him by the late Paul Grobler) and a Flaig’s FN Mauser action custom piece (which American client Zachary Miller originally had custom built for himself but gifted to Richard after a safari in 1973).

In conclusion, If you are buying a brand new dangerous game rifle… then, there are several better options available on the modern market than a .458 Winchester Magnum. But if a .458 Winchester Magnum is easily available to you and/or you already own one, the there’s absolutely no need to feel discouraged and discard it.

When I went on my life’s first African Safari to Kenya in 1974, I noticed that the game department law stipulated a minimum bore size of .400 caliber for hunting elephant & rhinoceros & Cape buffalo & hippopotamus. Due to Kynoch completely ceasing manufacture of centerfire ammunition in 1970, there were no commercially available cartridges for the traditional British large bore rifles of .400 caliber or above (since Kynoch was the only firm to ever manufacture any ammunition for them back in those days). And hand loading was illegal in Kenya. So basically, the .458 Winchester Magnum was the only caliber for which commercially manufactured .400+ caliber ammunition was available in Kenya (only Winchester since no gun shops in Kenya ever imported any Remington brand ammunition).

My white hunter, Mr, Cheffings considerately & discreetly permitted me to take my Cape buffalo (my life’s first one) with a .375 Holland & Holland Magnum (a BRNO ZKK-602 loaded with 1 RWS Kegelspitze 300Gr soft point & 5 RWS round nosed steel jacketed 300Gr FMJ solids). And I developed an immense life long respect for the .375 Holland & Holland Magnum immediately.

But I did later use a .458 Winchester Magnum to take this Cape buffalo on my 3rd African Safari (to Tanzania). It was a Belgium made boxlock ejector double rifle (a “Guild Gun”) and the ammunition comprised of hand loaded 500Gr Hornady soft points and round nosed steel jacketed FMJ solids. The fresh hand loads served me extremely well, and the Cape buffalo eventually folded after the first 2 shots. Although the rifle’s ejectors did fail to extract the expended cartridge cases from the breech after my 2 shots.

hoytcanon

AH fanatic

Undying and eternal love for the .458 Win...

It is not needed for most of the things I use it for, but it accomplishes the task in an entirely different fashion, and I am a big fan of this style of terminal ballistic results.

It is not needed for most of the things I use it for, but it accomplishes the task in an entirely different fashion, and I am a big fan of this style of terminal ballistic results.

an additional benefit is that every gunshop I have ever walked into in Africa has a few boxes of 458 Win on their shelf.

I'm am building a custom 458 Win at the moment, as the advent of high energy powder, and the recoil tradeoff is making the 458 Lott obsolete imo (unless you are a PH and is specifically looking for a stopper).

I also argue that a 458 Win leave space in the safe for a 500 Jeff, which is a real stopper.

I'm am building a custom 458 Win at the moment, as the advent of high energy powder, and the recoil tradeoff is making the 458 Lott obsolete imo (unless you are a PH and is specifically looking for a stopper).

I also argue that a 458 Win leave space in the safe for a 500 Jeff, which is a real stopper.

My uncle had a bolt action 458 and it was a beast with full house loads. However it can be loaded down to what ever level you like. Most of his loads were in the 45-70 range. Very accurate. If you’ve wanted one I’d say get it.

michael458

AH fanatic

LOVE.................

I first went to the field with 458 Winchester in 2000, Zimbabwe and later that year Mozambique. I was not after elephant or buffalo at the time, but lions primarily. I took 3 lions that year with a Winchester M70 458 Winchester 22 inch gun that I had picked up at a gun show in SC for $600.00, it is a control feed gun of course, and I was shooting only a 400 gr Swift A Frame at 2325 fps for my missions. I took the 3 lions, sable, kudu, zebra and several other assorted critters, and ever single one was DRT on the spot, it was impressive to me. From that point on, I loved .458 Caliber. I later added a Accurate Innovations stock and Leslie from the Custom Shop made a Lion Floor plate for the rifle. It has been retired for many years.

I left 458 Winchester shortly after, in favor of a Winchester M70 458 Lott Custom Shop gun, and carried it for a time, and then later another Custom Shop 458 Lott.......in 2005 I had an altercation with a Hippo at 6 steps, and the big long heavy 24 inch Winchester M70 458 Lott felt like a musket and was just not handy and as fast as I would have liked. This brought me to the various shorter B&M rifles in .500 caliber and .458 as well.....

I did have a 24 inch Winchester M70 Big Five Custom Shop gun, I did a lot of Pressure data and load data in 2013 with it. For some stupid reason I sold off most extra 458s, including Lotts and several other standard M70s as I knew I would never go to the field with any again. I kept two 458 Lotts and of course what I call my Lion Rifle, 458 Winchester. All the years between 2006 and up to 2014 I went to the field with various B&M rifles, one of my most favorite was a 18 inch Winchester M70 in 458 B&M, which equaled ballistically a 458 Winchester at 24 inches.

I never went back to the field after 2000-2001 with a 458 Winchester. In 2022 I found a bunch of 458 Win brass, and wanted to do some load data with some new bullets. I really did not want to drag the "Lion Rifle" out for this, so I figured to try one of the New Winchester M70s that were now made in SC, home state you know. I found a new gun, but I did not want that 24 inch musket barrel on it, so sent it out and had the barrel cut back to 20 inches, added a NECG Barrel band to it and went to work. My goal to make this rifle viable for the heavies, Elephant, buffalo, hippo, I needed or wanted a 450 gr CEB #13 Solid at 2200 fps, I could live with 2150, but really wanted 2200. After that, all other things would fall in place......... I was successful in my mission, getting the 450 #13 Solids to 2250-2275 fps all at or under 63000 PSI, most coming in at 60000 to 62500 PSI. More than enough to accomplish any mission asked of it. I also worked with 400 Hammers to over 2400 fps in the 20 inch gun, later some of the folks interested just "Hammered" buffalo with this bullet at a bit more velocity than my 20 inch gun would do, although 2400 is plenty. Some of the work done with this also lead to the development of a new CEB #13 Solid at 400 gr which is very nice as well. We are extremely pleased with our 20 inch 458 Winchester, it can get the job done with ease........... It has a plain jane Winchester Factory stock, nothing fancy......

Unfortunately right now I am suffering some issues with my right eye, and hell I can't see the iron sights at all, but we have high hopes that clears up soon. I have a 1X4 Nikon on the gun, but can't see that either. I am ready to put some ammo on the shelf for the 458 Wins, but would like to get some more data before doing so......... I may have to learn to shoot wrong handed for the wrong eye....?

As mentioned by a few, 458 Winchester no longer needs a 500 gr bullet to get the job done. Bullet Technology and new powders have come a long long way since its inception. Todays 450 gr bullets out perform in every aspect any 500 gr bullet that existed prior, by a long margin as well. You no longer need a 24 inch barrel, as proven. And in fact, I don't even recommend anything but the 450s even for larger capacity cartridges. In this case, less is MORE...........

I will always have a place for 458 Winchester............

I first went to the field with 458 Winchester in 2000, Zimbabwe and later that year Mozambique. I was not after elephant or buffalo at the time, but lions primarily. I took 3 lions that year with a Winchester M70 458 Winchester 22 inch gun that I had picked up at a gun show in SC for $600.00, it is a control feed gun of course, and I was shooting only a 400 gr Swift A Frame at 2325 fps for my missions. I took the 3 lions, sable, kudu, zebra and several other assorted critters, and ever single one was DRT on the spot, it was impressive to me. From that point on, I loved .458 Caliber. I later added a Accurate Innovations stock and Leslie from the Custom Shop made a Lion Floor plate for the rifle. It has been retired for many years.

I left 458 Winchester shortly after, in favor of a Winchester M70 458 Lott Custom Shop gun, and carried it for a time, and then later another Custom Shop 458 Lott.......in 2005 I had an altercation with a Hippo at 6 steps, and the big long heavy 24 inch Winchester M70 458 Lott felt like a musket and was just not handy and as fast as I would have liked. This brought me to the various shorter B&M rifles in .500 caliber and .458 as well.....

I did have a 24 inch Winchester M70 Big Five Custom Shop gun, I did a lot of Pressure data and load data in 2013 with it. For some stupid reason I sold off most extra 458s, including Lotts and several other standard M70s as I knew I would never go to the field with any again. I kept two 458 Lotts and of course what I call my Lion Rifle, 458 Winchester. All the years between 2006 and up to 2014 I went to the field with various B&M rifles, one of my most favorite was a 18 inch Winchester M70 in 458 B&M, which equaled ballistically a 458 Winchester at 24 inches.

I never went back to the field after 2000-2001 with a 458 Winchester. In 2022 I found a bunch of 458 Win brass, and wanted to do some load data with some new bullets. I really did not want to drag the "Lion Rifle" out for this, so I figured to try one of the New Winchester M70s that were now made in SC, home state you know. I found a new gun, but I did not want that 24 inch musket barrel on it, so sent it out and had the barrel cut back to 20 inches, added a NECG Barrel band to it and went to work. My goal to make this rifle viable for the heavies, Elephant, buffalo, hippo, I needed or wanted a 450 gr CEB #13 Solid at 2200 fps, I could live with 2150, but really wanted 2200. After that, all other things would fall in place......... I was successful in my mission, getting the 450 #13 Solids to 2250-2275 fps all at or under 63000 PSI, most coming in at 60000 to 62500 PSI. More than enough to accomplish any mission asked of it. I also worked with 400 Hammers to over 2400 fps in the 20 inch gun, later some of the folks interested just "Hammered" buffalo with this bullet at a bit more velocity than my 20 inch gun would do, although 2400 is plenty. Some of the work done with this also lead to the development of a new CEB #13 Solid at 400 gr which is very nice as well. We are extremely pleased with our 20 inch 458 Winchester, it can get the job done with ease........... It has a plain jane Winchester Factory stock, nothing fancy......

Unfortunately right now I am suffering some issues with my right eye, and hell I can't see the iron sights at all, but we have high hopes that clears up soon. I have a 1X4 Nikon on the gun, but can't see that either. I am ready to put some ammo on the shelf for the 458 Wins, but would like to get some more data before doing so......... I may have to learn to shoot wrong handed for the wrong eye....?

As mentioned by a few, 458 Winchester no longer needs a 500 gr bullet to get the job done. Bullet Technology and new powders have come a long long way since its inception. Todays 450 gr bullets out perform in every aspect any 500 gr bullet that existed prior, by a long margin as well. You no longer need a 24 inch barrel, as proven. And in fact, I don't even recommend anything but the 450s even for larger capacity cartridges. In this case, less is MORE...........

I will always have a place for 458 Winchester............

Last edited by a moderator:

hoytcanon

AH fanatic

LOVE.................

All the years between 2006 and up to 2014 I went to the field with various B&M rifles, one of my most favorite was a 18 inch Winchester M70 in 458 B&M...

I also worked with 400 Hammers to over 2400 fps in the 20 inch gun, later some of the folks interested just "Hammered" buffalo with this bullet at a bit more velocity than my 20 inch gun would do, although 2400 is plenty. Some of the work done with this also lead to the development of a new CEB #13 Solid at 400 gr which is very nice as well. We Unfortunately right now I am suffering some issues with my right eye, and hell I can't see the iron sights at all, but we have high hopes that clears up soon. I have a 1X4 Nikon on the gun, but can't see that either. I am ready to put some ammo on the shelf for the 458 Wins, but would like to get some more data before doing so......... I may have to learn to shoot wrong handed for the wrong eye....?

As mentioned by a few, 458 Winchester no longer needs a 500 gr bullet to get the job done. Bullet Technology and new powders have come a long long way since its inception. Todays 450 gr bullets out perform in every aspect any 500 gr bullet that existed prior, by a long margin as well. You no longer need a 24 inch barrel, as proven.

I also, love the .458 WM and share your affinity for carbines, although I prefer the Ruger flavor...

My latest .458 Carbine is an M77 Mark II Stainless with 20" Bob Jury barrel and NECG sights, I also mounted a Leupold VX-R 2-7X33, as my eyesight is failing as I age.

Members online

- jb1069

- Borderer

- grand veneur

- Fatback

- MT Griz

- towserthemouser

- Tubby’s Canteen

- WAB

- Boyd Brooks

- ACE (in CT)

- K E Johnson

- Beck

- mdwest

- Bowman

- matt2H

- Just a dude in BC

- odonata

- MontanaPat

- Piet Brood

- Sarg

- Indigo Earl

- RR 314

- Trappernewt

- Happy Myles

- Rando8586

- VertigoBE

- BryceM

- Edster

- forshoes

- Corey0372

- Schmidty

- Ravensview

- Dirtdart

- FARO EAST NORTH CAMEROON

- Rimbaud

- wesheltonj

- BeeMaa

- KuduKiller

- DieJager

- Bandera

- Est.1970

- Hififile324

- Caribou24

- trperk1

- DWB

- EVR

- roverandbrew

- a_alrumaidhi

- nomspc

- BJH65

Total: 68,149 (members: 1,240, guests: 66,909)

Forum statistics

Latest profile posts

Just Finished a great Buffalo and plains game combo hunt , pictures to follow soon!

Im interested in the Zeiss Scope. Any nicks or dings? Good and clear? I have on and they are great scopes