Our friend Brian from the far north went to Africa with his 24ga FH he did in

a NEF break action and got 3 nice buffs with it. Good job.

Our 585HE, 700HE and the great 12ga FH are now in the new COTW book

published in Oct, now out for sale,

We now have our target 375 HE cartridge, made by necking down our 585 HE.

The other couldn't make enough 375s, so we started our own. It has different

shoulder taper, length, neck length, improved over the other one...Got a bunch

guys doing it, most into the 2 mile shooting venues, We're making cases,

testing, reamer prints at reamer guys, we are getting guys going. King of 2 mile

shoot last year really got the interest booming for 375 necked from our case,

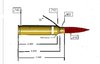

Here's how we size and seat 375 HE, a simple die, a 1" die, no huge dies needed

A die we can make with resize reamer from reamer guy, a regular die body,then

pass on to the next guy, one reamer can make whole bunch of dies for folks.

I do primer work separate, not in the press.That way I can clean pocket, check

flash hole,....... SO First with lock ring set, I size cases.

When coming back out of dies with case, we notice the case still well centered,

held straight, when it is down as far as the length of the 375 HE neck... IE

the sides and shoulder corner still supported tight. About .35" down.

So we put washer or another lock ring on, same thickness as neck length,

below original lock ring, screw down tight tight in press,

Dies had a 5/8 x 24 thread in top, had powder fill bushing and other stuff same thread,

reamed out from bottom to set bullet height, with ram, case,and bullet up,

After priming, loading in the powder charge, we carefully start(boat tail makes it easy)

bullet in case by hand, slide up in die, into holder, raise ram to to top, bullet seated

perfect. Die can have different thread in top as long as big enough to hold seating

bushing of some kind , that can be made from many items.

These target bullets held in by strong neck tension, no crimping needed, and notice

bullet point will get no marks or dents, fast, easy, no 380-500 buck special dies.

Bushing centering bullet on ogive is very accurate.

OVER 900 375HE cases piled behind presses getting done. About 600 on another

bench nearly ready. Small batches in shelves.And we will do more.

All 375 info, prints, specs, pictures, load data, etc, is public domain, worldwide,

for any target, hunting, etc, use..Ed