You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rifle Stock design/Felt Recoil: Chassis versus Wood/Laminated stock??

- Thread starter Gert Odendaal

- Start date

Gert Odendaal

AH legend

Inline, will it be possible to purchase the item along side the rifle in the photo? If possible it will for sure make my build easier.the magwell /front stock part??

Contact details of the good guy please Inline??

Contact details of the good guy please Inline??

Last edited:

Accuracy Obsession chassis is the company. Yes they do sell them. I know they are on facebook, I don't have a Facebook so I can't really help you out with that but I know they can be found.

Again so we are on the same page this is not a made to order any action. The inlet is only for an AI. It's also not cheap, 1200.00 us.

Again so we are on the same page this is not a made to order any action. The inlet is only for an AI. It's also not cheap, 1200.00 us.

Gert Odendaal

AH legend

Thank you, it will not work then for m y build project

Gert Odendaal

AH legend

The reason I went with the example in the photo I uploaded is it is a weighted design where weights are build /take off from the chassis while shooting and adjusting for recoil

Another reason is to mill it out from a Aluminum bar stock material

Another reason is to mill it out from a Aluminum bar stock material

Last edited by a moderator:

Gert Odendaal

AH legend

Brian, looking at the photo , I will be changing the design in the photo by adding/milling out the extra piece of aluminum all along the underside of the border on this butt stock..that will be where I will add the extra weights ...low down to the ground with the angle of 40 degrees , so as to nearly forming a triangle shape .

In the connection between the buttstock and action/magazine part I will insert a recoil damper into the connection shaft.

This is why I think the designers of this butt stock really did their home work in regards to the weighted system they designed into this chassis. Even at the bottom of the front end of the chassis there is about 400mm space where a long row of weights are bolted onto..as well as surfaces on the sides of the front end to bolt weights to..

It will not be a rifle to walk around with or carry in the bush or over any terrain for long periods, but that is not what it was intended for at all..

In the connection between the buttstock and action/magazine part I will insert a recoil damper into the connection shaft.

This is why I think the designers of this butt stock really did their home work in regards to the weighted system they designed into this chassis. Even at the bottom of the front end of the chassis there is about 400mm space where a long row of weights are bolted onto..as well as surfaces on the sides of the front end to bolt weights to..

It will not be a rifle to walk around with or carry in the bush or over any terrain for long periods, but that is not what it was intended for at all..

I would personally want the bottom of the stock as parallel to the ground as possible. When the rifle recoils you don't want the gun to dip, that why I would want it flat on the bottom personally. Just my opinion.

Gert Odendaal

AH legend

Looking at this butt stock..the small piece of rubber type of extrusion on this butt stock, will it be able to keep the rifle from dipping when recoiling??I would personally want the bottom of the stock as parallel to the ground as possible. When the rifle recoils you don't want the gun to dip, that why I would want it flat on the bottom personally. Just my opinion.

Last edited by a moderator:

Gert Odendaal

AH legend

I believe the front end on some of the chassis is one part functionality and one part esthetics ..

Brain, what do you prefer, a free floating barrel system of a fully bedded system on this rifle?

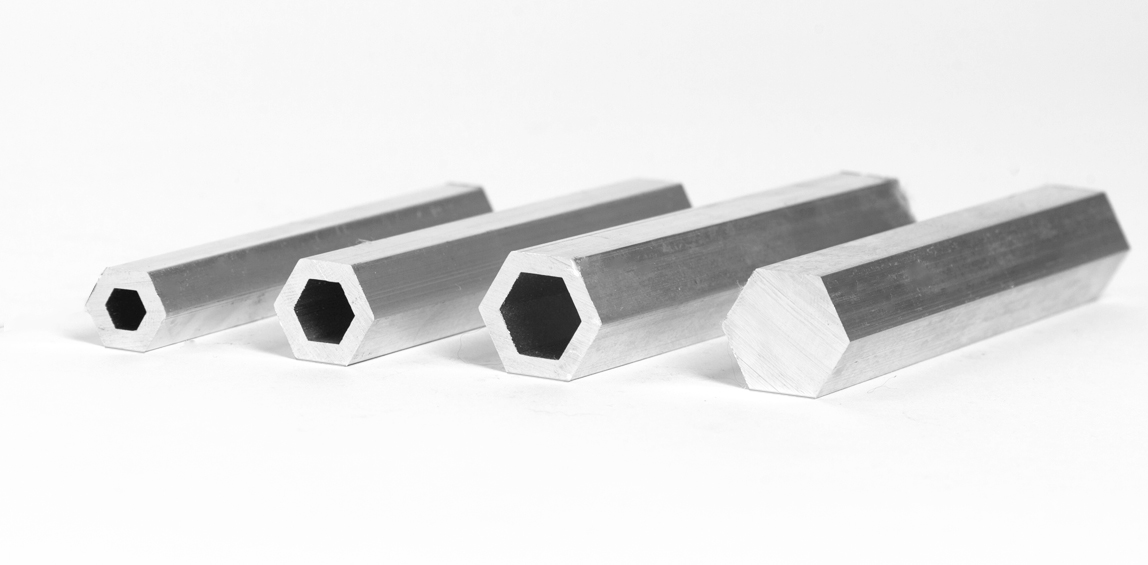

This hexagonal front aluminum tube will be a nice fun milling /drilling project from a solid piece of aluminum

Brain, what do you prefer, a free floating barrel system of a fully bedded system on this rifle?

This hexagonal front aluminum tube will be a nice fun milling /drilling project from a solid piece of aluminum

Last edited by a moderator:

Gert Odendaal

AH legend

Making use of products already available at the shops, a fun project for sure

Last edited by a moderator:

Gert Odendaal

AH legend

With pillar bedding??

Gert Odendaal

AH legend

This bullet choice I made to enable me to order a barrel for this project:

Take a look at these ballistics table of the Perigrine bullets in South Africa,

https://peregrinebullets.co.za/vrg4-lr-vrg5-lr/

With a 1:9.5 twist I can use a bullet with the BC of 0.681

Bullet choice:

I will be shooting the Perigrine VLR 4 , BC .0681 in a heavy straight taper barrel with a rifling twist of 1:9.5 the bullet weight 270 grain

The practice bullet:

Perigrine VLR5 , BC .0681 , 276 gn bullet

Barrel: Bartlein barrel blank" 30" inch 1:9.5 rifling , straight taper , .338 diameter $300 +shipping $30 = R4673.00

Take a look at these ballistics table of the Perigrine bullets in South Africa,

https://peregrinebullets.co.za/vrg4-lr-vrg5-lr/

With a 1:9.5 twist I can use a bullet with the BC of 0.681

Bullet choice:

I will be shooting the Perigrine VLR 4 , BC .0681 in a heavy straight taper barrel with a rifling twist of 1:9.5 the bullet weight 270 grain

The practice bullet:

Perigrine VLR5 , BC .0681 , 276 gn bullet

Barrel: Bartlein barrel blank" 30" inch 1:9.5 rifling , straight taper , .338 diameter $300 +shipping $30 = R4673.00

Attachments

I would look at the SS Max, no extra cost a little harder on tooling but not much and close to twice the barrel life.

I have some to load in my 375, I like what I see thus far. Will report how they perform. They are of high quality from what I see.

I have some to load in my 375, I like what I see thus far. Will report how they perform. They are of high quality from what I see.

Gert Odendaal

AH legend

Good, I spoke to a fellow rifle club member who shoots a .338 Lapua , he suggested I rather shoot the Perigrine Range Masters.

Bartlein 30" inch Stainless steel barrel, heavy straight taper , 1:9.5 twist

290 GN Perigrine Range Master bullets

BC = 0. 952

Bartlein 30" inch Stainless steel barrel, heavy straight taper , 1:9.5 twist

290 GN Perigrine Range Master bullets

BC = 0. 952

Gert Odendaal

AH legend

While waiting for my eye`s to heal after the surgery I am busy doing planning in regards to the manufacturing of the butt stock I want to design. I need to make a drawing of my own design .

Since I will be using the lost foam casting technique to cast the complete butt stock in high grade aluminum the patterns will be cut out from casting foam or Styrofoam to create the pattern by gluing it together in layers..this method will ensure a perfect design with very, very close tolerances.

The facing sand I will be using during the casting process will ensure extremely fine surfaces as well. The aluminum ingots will consist of high quality air craft grade aluminum .

The cavities in the butt stock will be cast using core sand that I will make myself to fit in the cavities of the pattern .

There still will be some surface grinding and milling work done on the casting to clean it up for a great shining result.

The main focus being the chassis milling work ..the practical skill thereof and the challenges to be as accurate as possible when milling the three parts of the chassis form a solid block of high grade aircraft aluminum.

I will be using this butt stock design to work from and make changes to it . The front end barrel cover will be cast as well.

Since I will be using the lost foam casting technique to cast the complete butt stock in high grade aluminum the patterns will be cut out from casting foam or Styrofoam to create the pattern by gluing it together in layers..this method will ensure a perfect design with very, very close tolerances.

The facing sand I will be using during the casting process will ensure extremely fine surfaces as well. The aluminum ingots will consist of high quality air craft grade aluminum .

The cavities in the butt stock will be cast using core sand that I will make myself to fit in the cavities of the pattern .

There still will be some surface grinding and milling work done on the casting to clean it up for a great shining result.

The main focus being the chassis milling work ..the practical skill thereof and the challenges to be as accurate as possible when milling the three parts of the chassis form a solid block of high grade aircraft aluminum.

I will be using this butt stock design to work from and make changes to it . The front end barrel cover will be cast as well.

Last edited by a moderator:

Gert Odendaal

AH legend

I did get conformation in regards to the suitability of using a HOWA .338 Win Mag barreled action from a gunsmith that works regularly on the Howa rifles and barreled actions to convert to long range shooting rifles. I will use the HOWA .338 Win Mag barreled action, ream the chamber to the .338 Imperial Magnum and use is as is with the Howa barrel in tact...after shooting out the barrel in the next four years time ( maybe) I can re-barrel to the Bartlein or Brux barrel a Shilen barrel will be great as well

..I need to keep in mind the HOWA barrel is only 24"inches long ..but this will really give me a lot of insight into shorter barrels vs long barrels on a long range shooting platform over the next four to five years..https://www.**NOT**PERMITTED**.co.za/forums/images/smilies/happy0065.gif

..I need to keep in mind the HOWA barrel is only 24"inches long ..but this will really give me a lot of insight into shorter barrels vs long barrels on a long range shooting platform over the next four to five years..https://www.**NOT**PERMITTED**.co.za/forums/images/smilies/happy0065.gif

I spend some time on the internet today to source a hexagon extrusion aluminum pipe..nowhere in South Africa is this item available at all. So I need to do some creative thinking to sort out this challenge. I think maybe going the round pipe route and mill out a long picatinny steel rail to bolt onto the top of the aluminum pipe cover for the barrel..I think it is more about esthetics and looks than having a place to fit items to the chassis. So I will cast/mill as many parts of the butt stock and front end barrel cover as possible.

..I need to keep in mind the HOWA barrel is only 24"inches long ..but this will really give me a lot of insight into shorter barrels vs long barrels on a long range shooting platform over the next four to five years..https://www.**NOT**PERMITTED**.co.za/forums/images/smilies/happy0065.gif

..I need to keep in mind the HOWA barrel is only 24"inches long ..but this will really give me a lot of insight into shorter barrels vs long barrels on a long range shooting platform over the next four to five years..https://www.**NOT**PERMITTED**.co.za/forums/images/smilies/happy0065.gifI spend some time on the internet today to source a hexagon extrusion aluminum pipe..nowhere in South Africa is this item available at all. So I need to do some creative thinking to sort out this challenge. I think maybe going the round pipe route and mill out a long picatinny steel rail to bolt onto the top of the aluminum pipe cover for the barrel..I think it is more about esthetics and looks than having a place to fit items to the chassis. So I will cast/mill as many parts of the butt stock and front end barrel cover as possible.

Members online

- Travis Johnson

- Dieseljzanzibar

- DLSJR

- Rob Sparks

- BlueFlyer

- Bushkey

- 318AE

- WesRic404Jeff

- Lem

- Beethoven

- Riflecrank

- gizmo

- CurtisDees

- Woodcarver

- Vitahunt

- Kevin Peacocke

- Scott63

- Fordy

- Jhsmith

- CBH Australia

- vbert

- KoedoePoesPienk

- Shiverz

- Flbt

- Steve O

- Nevada Wapati

- model70left

- Alistair

- Alex38

- dchum

- PHOENIX PHIL

- Riksa

- FlowHamed18

- Happy Myles

- jnelson

- Jakob

- Tman321

- Kurt Swanson

- 04sika

- Skshyk

- DERIAN KOEKEMOER SAFARIS

- HUNTROMANIA

- DWB

- WoodencrossIII

- Killo

- StevenQ718

- Charles.Williams04

- 1:66 twiste@d

- Piet Brood

- TERMINATOR

Total: 80,900 (members: 1,205, guests: 79,695)

Forum statistics

Latest profile posts

Just received your book. It will be a Christmas present from my wife. Looking forward to read it.

Jake, Sorry to bug you again. I was wondering if you could share a. couple actual pics of this crossbow with me?

Thank you Ferenc

Xpedition Archery USED Scrapeline390X Sniper Gray Crossbow XACW1001 - Light Wear - Needs Bolt/Arrow Guide Spring UA5689

If it is in a decent shape, would you be willing to sell it for $100 shipped? IS it missing the retention spring that goes over the bolt?Thank you Ferenc

Hie guys. Where can a 16 year old get a job at a hunting outfitter whilst the boy studies for lph . If anyone has anything WhatsApp me on [redacted]

Good morning John, I just read your setup procedure for the northstar duplicator ator. I found it very hand and I did learn some things. I have the same machine and I am having a problem i can not figure out and was hoping you could shed some light on the subject.

I'll take the 375 bullets. I'm not a techie, so I can do USPS money order or Paypal?

My telephone is [redacted] Thanks, S.

My telephone is [redacted] Thanks, S.