Tin is mostly to break the surface tension so the mold can fill out better and only about 1.5% is needed. Antimony makes for a hard alloy but, as someone said it will shatter if too much. A little copper in the PB SB Sn alloy makes it somewhat harder but, more important, makes it tougher so as not to shatter, or so I am told. I have never tried such a hard and tough alloy because 12-15 BHN is all I've needed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hunting with cast lead bullets

- Thread starter njc110381

- Start date

nztimb

AH ambassador

We have been using babbit for the copper content and getting the toughness and hardness up into the high 20's BHN without the brittless and allows for high velocity with the nose performance to take game.

For my 2400fps 160gn 7x57 bullet I used a 100gn lno shank with 60gn 50/50 nose in a bore riding bullet.

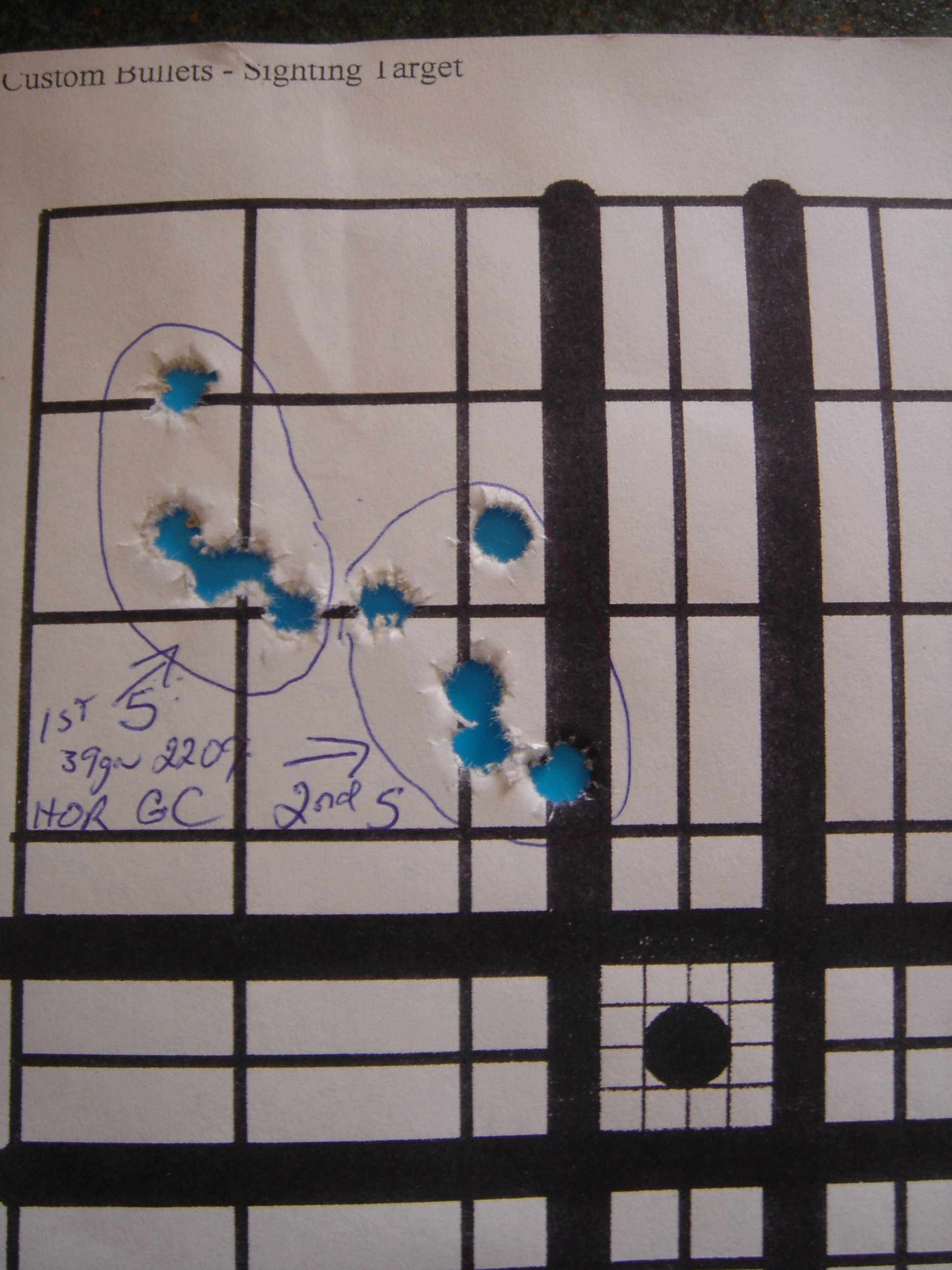

Getting the scope dialled in for this load and at 2416fps it is an easy 200yd load. Next adjustmant (R 2 clicks) had it right at right where I wanted it at 100yds.

For my 2400fps 160gn 7x57 bullet I used a 100gn lno shank with 60gn 50/50 nose in a bore riding bullet.

Getting the scope dialled in for this load and at 2416fps it is an easy 200yd load. Next adjustmant (R 2 clicks) had it right at right where I wanted it at 100yds.

bruce moulds

AH legend

- Joined

- Aug 10, 2018

- Messages

- 2,871

- Reaction score

- 4,864

very good von gruff.

I recall ross seyfried doing similar, but his bullets looked nowhere as good as yours pre firing.

bruce.

I recall ross seyfried doing similar, but his bullets looked nowhere as good as yours pre firing.

bruce.

nztimb

AH ambassador

Thanks Bruce. I made a ot of the 50/50 bullets then cut the nose of and sized it to just under as cast dia.very good von gruff.

I recall ross seyfried doing similar, but his bullets looked nowhere as good as yours pre firing.

bruce.

I would put a nose in the mould (use fine nedlenose pliers to keep fingers away from thr heat

= experience) and fill with lino eavinf a decent sprue puddle when that had silvered off I put the mould into the pt till the sprue starts to shine telling me it both alloys have melted and become one so there was no danger of them breaking at the join. You can see from the pic in the previous post how well they he;d together. I would have a wet towel handle and a fan that I could start the cooling process but waited till sprue was well set before turning out the bullet and starting on the next one. Weight difference bullet was generally in the dismissable area so these were very accurate bullets and one that was better than the NP in its weight retention. Killed a lot of goats with them.

= experience) and fill with lino eavinf a decent sprue puddle when that had silvered off I put the mould into the pt till the sprue starts to shine telling me it both alloys have melted and become one so there was no danger of them breaking at the join. You can see from the pic in the previous post how well they he;d together. I would have a wet towel handle and a fan that I could start the cooling process but waited till sprue was well set before turning out the bullet and starting on the next one. Weight difference bullet was generally in the dismissable area so these were very accurate bullets and one that was better than the NP in its weight retention. Killed a lot of goats with them.bruce moulds

AH legend

- Joined

- Aug 10, 2018

- Messages

- 2,871

- Reaction score

- 4,864

good post von gruff.

just shows what you can do if you have a go.

bruce.

just shows what you can do if you have a go.

bruce.

Ridge Runner

AH legend

- Joined

- Mar 23, 2017

- Messages

- 4,658

- Reaction score

- 10,090

- Media

- 31

- Member of

- NMLRA, SCI,

- Hunted

- East Cape, South Africa, Zimbabwe

I just started reading this thread so I don't know what all the others have posted. I'll most likely reiterate what others have already posted.

Your OP is about using cast bullets, others, that I have thus far read, talk about paper patch.

You are asking and saying you want to cut cost ....there by save on ammo costs.

It's all about metallurgy!! When it comes to casting bullets!!!

Variables ... Variables..... Variables!!!!????

Your OP is relatively vague.

For plains game: range, caliber, velocities wanted-----velocities needed-----velocities required??????

For dangerous game: range, caliber, mandatory velocities and PENATRATION!!!

I WOULD NOT recommended any lead base bullet for dangerous game, WITH EXCEPTION OF CATS, AND CROCS. Why? Because of the thick hide, mussle, and fat!

Wheel weights...too much variation in compounds to reproduce the same BC from batch to batch. Bullets from wheel weights CAN BE....BUT NOT NECESSARILY .....HARD ON.....,.rifling!

Research, Research, Research......

Experiment, Experiment, Experiment....

Test, Test, Test....

Research historical records.... What was hunted by those of the black powder/muzzleloading era and black powder cartridge era. And the calibers they used on various game.

Experiment (test) your loads, i.e. the phone book and then on game small to big...know the limits of your caliber firearm.

Test your loads starting with small critters and work your way up to bigger animals until you reach the optimum size of powder charge to bullet weight/caliber to animal.

Now, to using lathe and round bar stock, copper alloys for solids for dangerous game bullets. New chapter. MORE research. More math. More experimenting.

I mentioned black powder because what our fore farthers used is a starting point. By Converting black powder load pressures to smokeless equivalent grain weights and pressures and you now have a starting point for loading any type of cartridge.

Your OP is about using cast bullets, others, that I have thus far read, talk about paper patch.

You are asking and saying you want to cut cost ....there by save on ammo costs.

It's all about metallurgy!! When it comes to casting bullets!!!

Variables ... Variables..... Variables!!!!????

Your OP is relatively vague.

For plains game: range, caliber, velocities wanted-----velocities needed-----velocities required??????

For dangerous game: range, caliber, mandatory velocities and PENATRATION!!!

I WOULD NOT recommended any lead base bullet for dangerous game, WITH EXCEPTION OF CATS, AND CROCS. Why? Because of the thick hide, mussle, and fat!

Wheel weights...too much variation in compounds to reproduce the same BC from batch to batch. Bullets from wheel weights CAN BE....BUT NOT NECESSARILY .....HARD ON.....,.rifling!

Research, Research, Research......

Experiment, Experiment, Experiment....

Test, Test, Test....

Research historical records.... What was hunted by those of the black powder/muzzleloading era and black powder cartridge era. And the calibers they used on various game.

Experiment (test) your loads, i.e. the phone book and then on game small to big...know the limits of your caliber firearm.

Test your loads starting with small critters and work your way up to bigger animals until you reach the optimum size of powder charge to bullet weight/caliber to animal.

Now, to using lathe and round bar stock, copper alloys for solids for dangerous game bullets. New chapter. MORE research. More math. More experimenting.

I mentioned black powder because what our fore farthers used is a starting point. By Converting black powder load pressures to smokeless equivalent grain weights and pressures and you now have a starting point for loading any type of cartridge.

Last edited:

Bob Nelson 35Whelen

AH ambassador

- Joined

- Oct 28, 2018

- Messages

- 13,028

- Reaction score

- 33,054

- Location

- Wyong new south Wales Australia

- Media

- 130

- Member of

- SSAA

- Hunted

- Australia

@5shotI have wanted to try paper patching. I have been shooting a lot of cast in my 35 Whelen AI and 47-70 Ruger #1, and they are super accurate, so I haven't experimented much. How fast can you drive a paper patch slug with such a low BHN?

What weight were you using in your WHELAN AI and what load. How did they work on game. Would love to try it in my Whelen.

Bob

@5shot

What weight were you using in your WHELAN AI and what load. How did they work on game. Would love to try it in my Whelen.

Bob

My best load is with a 300 grain hollow point. I am using H380 (load from Hodgdon #26). Prints damn small groups. Mold is from NOE.

Bob Nelson 35Whelen

AH ambassador

- Joined

- Oct 28, 2018

- Messages

- 13,028

- Reaction score

- 33,054

- Location

- Wyong new south Wales Australia

- Media

- 130

- Member of

- SSAA

- Hunted

- Australia

@ 5shot

What velocities are you getting from that and are they gas checked.

Bob

Bob Nelson 35Whelen

AH ambassador

- Joined

- Oct 28, 2018

- Messages

- 13,028

- Reaction score

- 33,054

- Location

- Wyong new south Wales Australia

- Media

- 130

- Member of

- SSAA

- Hunted

- Australia

@Kawshik RahmanIt is not that they do not kill animals. They certainly do. The Shawtal poachers in India , especially Darjeeling where l was a Shikari until 1970 , would mould and cast their own round lead bullets and harden them over fires for their locally made matchlock smoothbore guns illegally . These bullets would weigh invariably between two to three ounces ( given the cottage industry type nature of manufacturing these crude weapons , a bore size was never made standard ) and even were used successfully on female elephants ( two of the three elephants shot before my very eyes , were killed with such arms and bullets ) if the elephant was shot in the side of the head where it’s skull is thin at close distances. I have a picture of one such incident.

However , from a philosophical point of view , a client pays thousands of dollars ( it used to be rupees in my case) to go on a safari which for many , is a once in whole life experience.Certainly frugality should be ignored in such a case and good ammunition should be sourced. Substandard ammunition would often turn an enjoyable shikar into a strenuous task. My most troublesome Shikars were when some American clients would come with a .3006 and cartridges with pointed bullets which were invariably purchased from surplus army stores in green containers. Those kinds of ammunitions with pointed heads were very cheaply acquired for the .3006 but they were horrible for hunting animals.

I have cast many lead bullets for a magnum.22 rifle which l own and they see use on troublesome foxes and a few hares for the pot . But for serious hunting , l would opt for good ammunition unless you have extensive knowledge on metal alloys.

I pray you are keeping safe and well my friend and enjoying shikar times with friends @ Major Poton Kahn and @Panther Shooter.

Your friend

Bob Nelson.

I have a 434 grn GC bullet from a mold that Robert Applegate made me that was initially designed for use in a Marlin. If you ever want to try them out, give me a shout.

I have an Applegate mold,too. Robert designed this as the heaviest one to cycle in Marlins,mine drops 470 grains.

I bought this some 20 years ago. I have not seen these around much. Great quality!

Bullets in the pic are Hi Tek coated.

Last edited by a moderator:

Brickman301

AH member

I’ve use cast bullets to take deer. Here’s a post I posted elsewhere of the performance I had on a 8 point buck last season.

Enjoy!

I took a deer with my Marlin 45-70. The loads is 47.5 grains of 3031. The bullet is a Lyman Gould bullet. I cast this bullet using pure lead, and it is then powder coated. Once completed the bullet weights 344 grains.

I’ve used this load to take numerous deer over the years, and have always had complete pass throughs.

This deer was taken at a little farther distance than any of the others, (range finder said 147 yards) and did not pass through! I was excited about this, as I’ve always wanted to recover my bullet to see how it performs.

I was able to recover the bullet, and couldn’t be happier with how well it did.

The bullet started out as .456 in diameter and expanded to .974!

It only lost 3.9 grains of weight!

Pretty much as perfect as it can get!

Here’s some pictures of the bullet, before and after

Enjoy!

I took a deer with my Marlin 45-70. The loads is 47.5 grains of 3031. The bullet is a Lyman Gould bullet. I cast this bullet using pure lead, and it is then powder coated. Once completed the bullet weights 344 grains.

I’ve used this load to take numerous deer over the years, and have always had complete pass throughs.

This deer was taken at a little farther distance than any of the others, (range finder said 147 yards) and did not pass through! I was excited about this, as I’ve always wanted to recover my bullet to see how it performs.

I was able to recover the bullet, and couldn’t be happier with how well it did.

The bullet started out as .456 in diameter and expanded to .974!

It only lost 3.9 grains of weight!

Pretty much as perfect as it can get!

Here’s some pictures of the bullet, before and after

Attachments

Wyatt Smith

AH legend

Here is the extent of my cast bullet hunting, a 41 mag with the RCBS 41-210 SWC.

This fall I will use cast bullets the out my 45-70 (the mold is in the mail currently).

I would like to get another with a sixgun, probably the 41 again or an old model Blackhawk 45 colt.

Bob Nelson 35Whelen

AH ambassador

- Joined

- Oct 28, 2018

- Messages

- 13,028

- Reaction score

- 33,054

- Location

- Wyong new south Wales Australia

- Media

- 130

- Member of

- SSAA

- Hunted

- Australia

@Wyatt SmithView attachment 704325

Here is the extent of my cast bullet hunting, a 41 mag with the RCBS 41-210 SWC.

This fall I will use cast bullets the out my 45-70 (the mold is in the mail currently).

I would like to get another with a sixgun, probably the 41 again or an old model Blackhawk 45 colt.

Love the Von Gruff knife mate.

Bob

Members online

- KTMpilot

- Altitude sickness

- Frontier3006

- DocHolliday

- JMM

- Elkeater

- SS hunter

- cash_tx

- Aaron.F

- godwincp

- Rubi_300

- mgstucson

- Hyena

- raamw

- pilar

- Hornedfrogbbq

- Uncontrolled_round_feed

- BeeMaa

- Bwanared

- Saysaw0509

- WI-2021

- WesRic404Jeff

- MRBlack

- Adam S

- DillonG

- D.L.W.

- Beretta391

- BJH65

- Rakman

- fritzy2

- HWL

- bcoving

- Peter Larsson

- DieJager

- thoma018

- Jefferry404

- Captain Munro

- mutedblade

- Albert GRANT

- ianevans

- Old3Toe

- Rare Breed

- Berettaco

- mms45

- fidelh

- Tommen

- jonessaddle

- bobdahunter84

- Choupique

- jpg

Total: 92,961 (members: 1,065, guests: 91,896)

Forum statistics

Latest profile posts

thanks for your reply bob , is it feasible to build a 444 on a P14/M17 , or is the no4 enfield easier to build? i know where i can buy a lothar walther barrel in 44, 1-38 twist , but i think with a barrel crown of .650" the profile is too light .

I have quite a bit of 458 win mag brass, most of it new. How much are you looking for?

Ray H

Ray H

hey bob , new on here. i specifically joined to enquire about a 444 you built on a Enfield 4-1 you built . who did the barrel and what was the twist and profile specs ? look foward to your reply . cheers