One Day...

AH legend

Let me illustrate, using some additional AutoCAD sketches (not to scale)

This is completely different from what happens during ejection:

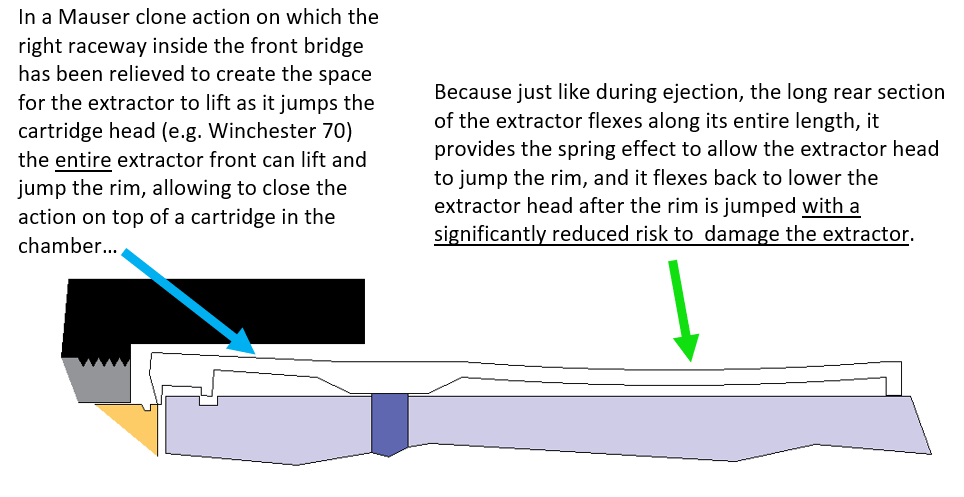

One also needs to realize that some actions are designed from the inception to allow the extractor to jump the rim. This is the case of the more recent CRF Winchester 70:

Whether beveling the extractor on a military Mauser (or clone), or cutting a relief in the right raceway inside the front bridge as in a Winchester 70, either of which create the space for the extractor to jump the rim of a cartridge inserted directly in the chamber, is an “improvement” on the Mauser design because it supposedly allows to perform an emergency single reload faster, is a matter of personal judgement.

Mauser aficionados disagree because:

1) A hurried reload is generally faster when clicking a cartridge in the magazine because dropping a cartridge on top of the magazine, or inserting it directly in the barrel by hand, is generally slower because it often results in catching the tip of the bullet on the rear edge of the chamber, especially with truncated solids... especially in a rush... especially in movement... especially under pressure...

2) Allowing the extractor to jump the rim of a cartridge in the chamber defeats the very purpose of the Mauser system extractor, by:

What makes the controlled round feeding (CRF) and external extractor of the Mauser system unique is that they precisely make it physically impossible for the extractor to jump the rim and fail to extract, or load the rifle accidentally.

Removing these features essentially converts the Mauser action to just another derivation of a push feed system as even a big external claw extractor, unsupported by the wall of the front bridge, has neither more nor less chances to fail to extract than any other extractor design.

I hope this helps understand the Mauser system, and the pros & cons of modifying it

This is completely different from what happens during ejection:

One also needs to realize that some actions are designed from the inception to allow the extractor to jump the rim. This is the case of the more recent CRF Winchester 70:

Whether beveling the extractor on a military Mauser (or clone), or cutting a relief in the right raceway inside the front bridge as in a Winchester 70, either of which create the space for the extractor to jump the rim of a cartridge inserted directly in the chamber, is an “improvement” on the Mauser design because it supposedly allows to perform an emergency single reload faster, is a matter of personal judgement.

Mauser aficionados disagree because:

1) A hurried reload is generally faster when clicking a cartridge in the magazine because dropping a cartridge on top of the magazine, or inserting it directly in the barrel by hand, is generally slower because it often results in catching the tip of the bullet on the rear edge of the chamber, especially with truncated solids... especially in a rush... especially in movement... especially under pressure...

2) Allowing the extractor to jump the rim of a cartridge in the chamber defeats the very purpose of the Mauser system extractor, by:

2a- making it possible for the extractor to also jump the rim when the action is opened, hence creating the potential for extraction failure: if there is space for the extractor to jump the rim when closing the bolt, this space continues to exist for the extractor to jump the rim when opening the bolt;

2b- making it possible to close the bolt on a cartridge unknowingly left in the chamber, hence creating the potential for an accidental discharge. I personally know a PH who witnessed such an accident, which resulted in a woman getting killed.

What makes the controlled round feeding (CRF) and external extractor of the Mauser system unique is that they precisely make it physically impossible for the extractor to jump the rim and fail to extract, or load the rifle accidentally.

Removing these features essentially converts the Mauser action to just another derivation of a push feed system as even a big external claw extractor, unsupported by the wall of the front bridge, has neither more nor less chances to fail to extract than any other extractor design.

I hope this helps understand the Mauser system, and the pros & cons of modifying it

Last edited:

, and I will hasten to say that I only have a very limited experience compared to folks whose job it is to work with (e.g. gunsmiths) or around (e.g. PHs) rifles, the failures are:

, and I will hasten to say that I only have a very limited experience compared to folks whose job it is to work with (e.g. gunsmiths) or around (e.g. PHs) rifles, the failures are: what must have been way, way, way above specs extraction tests (I fired a few shots to verify whether it was a single round fluke or a systemic problem, which it was).

what must have been way, way, way above specs extraction tests (I fired a few shots to verify whether it was a single round fluke or a systemic problem, which it was).