buckstix

AH fanatic

- Joined

- Jun 18, 2013

- Messages

- 525

- Reaction score

- 1,286

- Website

- www.buckstix.com

- Media

- 22

- Member of

- NRA LIFE MEMBER

- Hunted

- US - CANADA

40 cal Rigby, Dublin - Big Bore ?? Rook & Rabbit Rifle Needle Gun

Hello All,

I bought this at auction a couple weeks back and was surprised at what I got. As you can see from the listing, I thought I was buying an early Rigby single shot "center-fire" cartridge gun. But, after some research, I found out it was a Needle Gun. Here are some of the references I found:

[color:GREEN]"... John Rigby & Company founded by John Rigby in 1775 in Dublin. His grandson, also John, opened a London branch in 1865. After conducting multiple experiments beginning in 1824, Prussian gunsmith Johann Nikolaus von Dreyse in 1836 produced the first complete needle fire gun and founded a firearms factory in the town. ... John Rigby and W.N.Norman's Patent No.899 of April, 1860. A very early breech loading patent that used paper needle fire shells. The breech is opened by lifting the bolt straight up which un-threads a shaft that fits into the barrel, thus holding the barrel tight on face when shut. These distinctive rook rifles were based on part of the Rigby & Norman patent (No. 899 of 1860) and were described by Rigby in their records as ‘Improved Needle Rifle’ and marketed as “The Bijou”. .... Octagonal barrel with full length matted top flat signed “JOHN RIGBY & CO. DUBLIN” and fitted with a bead front sight and rear sight of one standing notch sight and two folding leaves graduated to “150” yards ... The breech end of the barrel a separate piece which is casehardened and engraved with foliate scrollwork. Casehardened border and scroll engraved action signed “JNO. RIGBY & CO.” on the left side, and with blued flat lever for the screw breech with checkered tip and blued hammer with long ‘needle’ firing pin. Casehardened trigger guard and butt plate engraved ... the forearm with key fastener and shaped green horn tip ... Birmingham black powder proof marks..."[/color]

That's why there is no extractor because the intended paper wrapped cartridge is totally consumed upon firing.

The first set of pictures show detail about the rifle.

Since I always intend to shoot every gun I own, I set about developing a way to shoot this interesting rifle. Rather than making paper cartridges like the originals from the 1850's, I set about producing metallic cartridges that would work in their place. It took about 20 hours to produce 10 centerfire cartridges for the rifle. I had to create a special "dual head" cartridge to fit into the recess of the screw-bolt's face.

The second set of pictures show the cartridge making process.

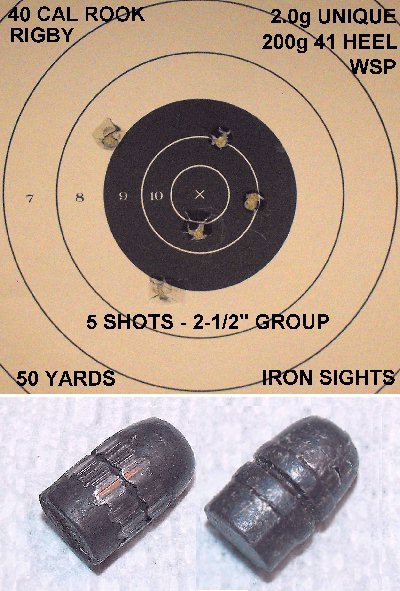

When loading for these old vintage antique rifles I always error on the conservative side. Note the engraved bullet that stopped 1/2" short of making it out of the barrel. That was from the first conservative loading with 1.5g Unique. After the load was increased to 2g, all left the barrel as intended. I love shooting a 165 year old rifle that likely stayed dormant for over a hundred & twenty five years.

The third set of pictures show the shooting results.

Hello All,

I bought this at auction a couple weeks back and was surprised at what I got. As you can see from the listing, I thought I was buying an early Rigby single shot "center-fire" cartridge gun. But, after some research, I found out it was a Needle Gun. Here are some of the references I found:

[color:GREEN]"... John Rigby & Company founded by John Rigby in 1775 in Dublin. His grandson, also John, opened a London branch in 1865. After conducting multiple experiments beginning in 1824, Prussian gunsmith Johann Nikolaus von Dreyse in 1836 produced the first complete needle fire gun and founded a firearms factory in the town. ... John Rigby and W.N.Norman's Patent No.899 of April, 1860. A very early breech loading patent that used paper needle fire shells. The breech is opened by lifting the bolt straight up which un-threads a shaft that fits into the barrel, thus holding the barrel tight on face when shut. These distinctive rook rifles were based on part of the Rigby & Norman patent (No. 899 of 1860) and were described by Rigby in their records as ‘Improved Needle Rifle’ and marketed as “The Bijou”. .... Octagonal barrel with full length matted top flat signed “JOHN RIGBY & CO. DUBLIN” and fitted with a bead front sight and rear sight of one standing notch sight and two folding leaves graduated to “150” yards ... The breech end of the barrel a separate piece which is casehardened and engraved with foliate scrollwork. Casehardened border and scroll engraved action signed “JNO. RIGBY & CO.” on the left side, and with blued flat lever for the screw breech with checkered tip and blued hammer with long ‘needle’ firing pin. Casehardened trigger guard and butt plate engraved ... the forearm with key fastener and shaped green horn tip ... Birmingham black powder proof marks..."[/color]

That's why there is no extractor because the intended paper wrapped cartridge is totally consumed upon firing.

The first set of pictures show detail about the rifle.

Since I always intend to shoot every gun I own, I set about developing a way to shoot this interesting rifle. Rather than making paper cartridges like the originals from the 1850's, I set about producing metallic cartridges that would work in their place. It took about 20 hours to produce 10 centerfire cartridges for the rifle. I had to create a special "dual head" cartridge to fit into the recess of the screw-bolt's face.

The second set of pictures show the cartridge making process.

When loading for these old vintage antique rifles I always error on the conservative side. Note the engraved bullet that stopped 1/2" short of making it out of the barrel. That was from the first conservative loading with 1.5g Unique. After the load was increased to 2g, all left the barrel as intended. I love shooting a 165 year old rifle that likely stayed dormant for over a hundred & twenty five years.

The third set of pictures show the shooting results.

Last edited by a moderator: