Shooter375

AH veteran

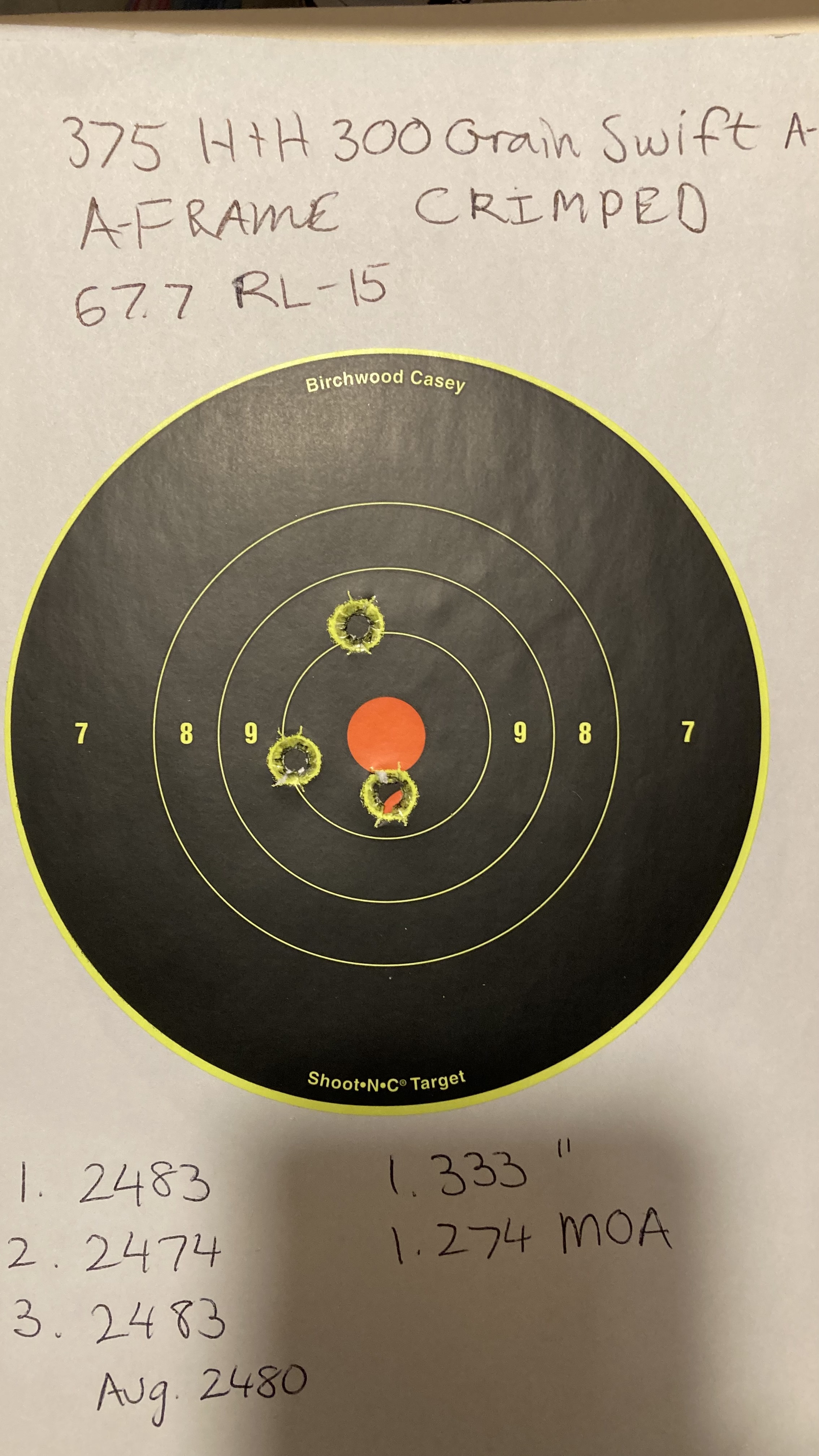

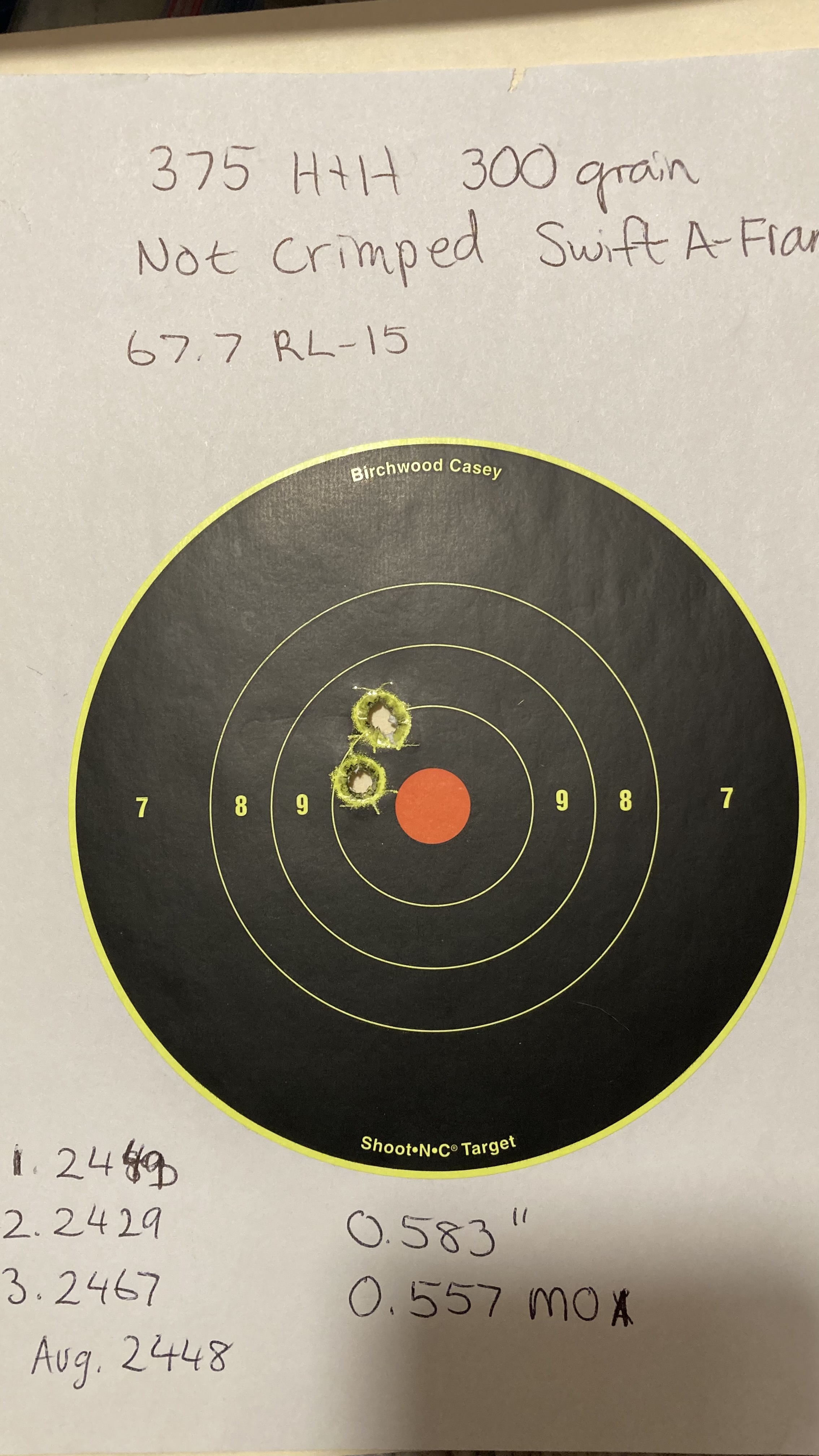

To crimp or not to crimp, that is the question? I tried a little experiment to examine the effects on accuracy of crimping. I shot six identical rounds with one exception. The exception being that three were crimped with a Lee Factory Crimp die and three that were left uncrimped. These are the results.

There is a significant difference in accuracy.

There is a significant difference in accuracy.

1.274 MOA (crimped) vs. 0.557 MOA (uncrimped)

Other differences include a decrease in velocity for the uncrimped rounds. 2480 fps (crimped) vs. 2448 fps (uncrimped).

Uncrimped

Crimped

Uncrimped

Uncrimped

Crimped

Fired from my Kimber Caprivi in 375 H&H.

Fired from my Kimber Caprivi in 375 H&H.

I think, based upon these results, I will use an uncrimped round for the first round and fill the magazine with crimped rounds which will hold up better under recoil. Is a 1/2 inch of accuracy worth it? What do you guys think?

1.274 MOA (crimped) vs. 0.557 MOA (uncrimped)

Other differences include a decrease in velocity for the uncrimped rounds. 2480 fps (crimped) vs. 2448 fps (uncrimped).

Uncrimped

Crimped

Crimped

I think, based upon these results, I will use an uncrimped round for the first round and fill the magazine with crimped rounds which will hold up better under recoil. Is a 1/2 inch of accuracy worth it? What do you guys think?

Last edited: