rdog

AH elite

- Joined

- May 25, 2021

- Messages

- 1,087

- Reaction score

- 3,383

- Location

- sunshine coast QLD Australia

- Media

- 18

- Member of

- SSAA

After lots of thinking about how to weld on a couple of M98 bolt handles for my 318 WR projects i originally

was going to use a Mig welder, but ended up buying a Tig welder for Xmas.

Spent a couple of days practicing & fiddling with the welders adjustments

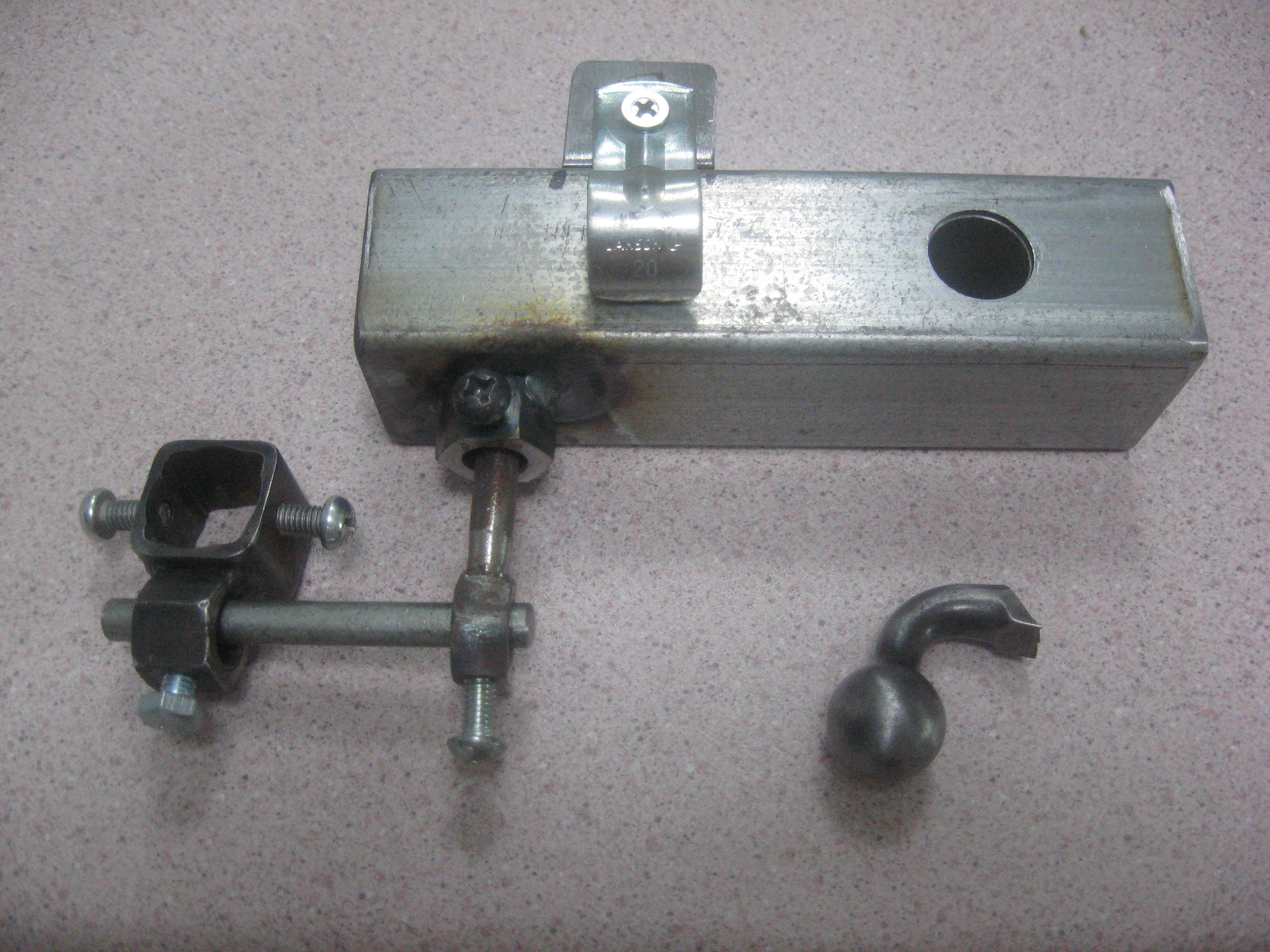

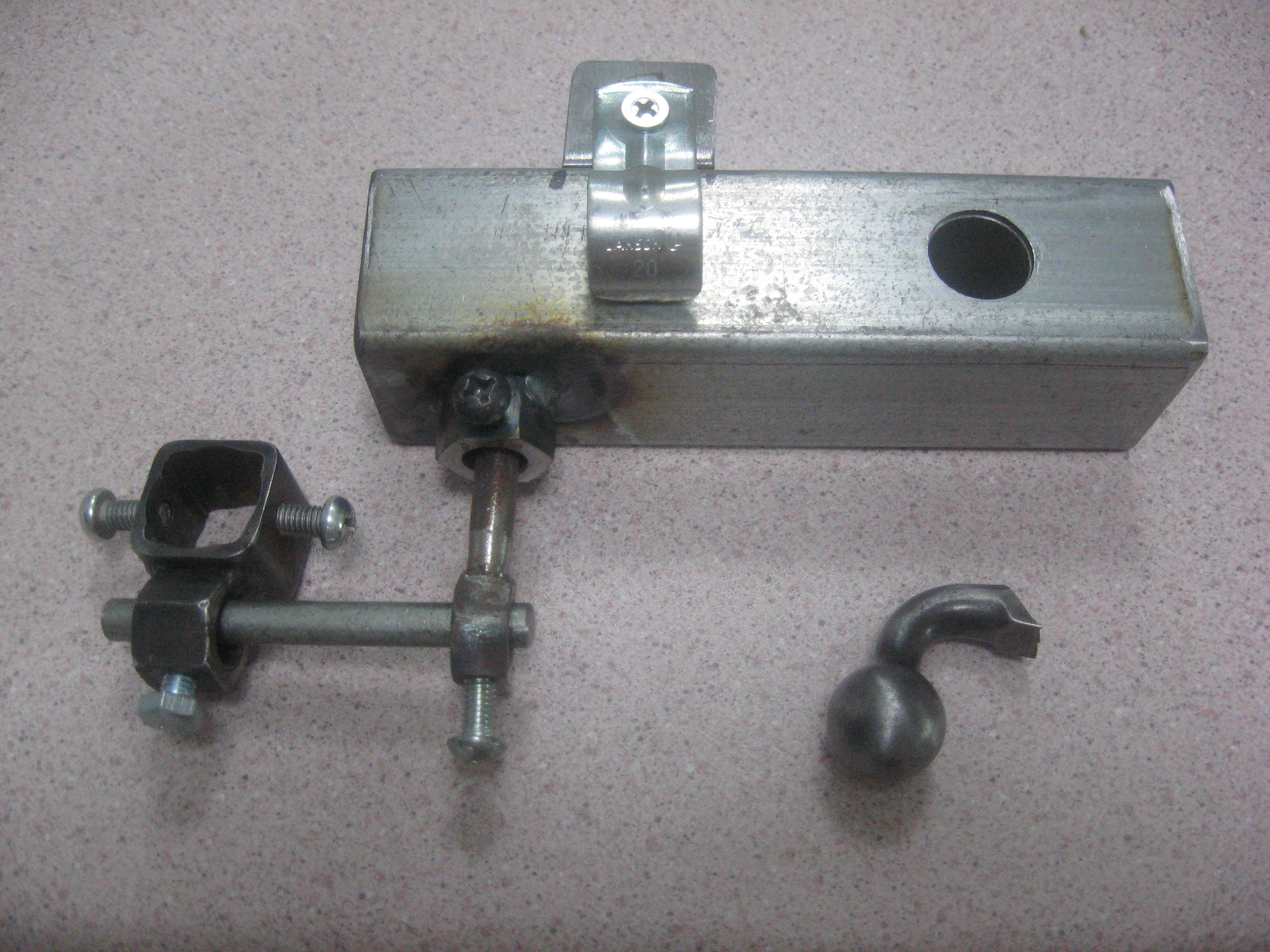

brought a bolt heat sink & 2 Talley bolt handles from Brownells . Heat blocking putty from the local plumbing supply shop, Made a bolt handle alignment jig

out of material i had laying around. Here is the results the next one will take halve the time & be a better job.

was going to use a Mig welder, but ended up buying a Tig welder for Xmas.

Spent a couple of days practicing & fiddling with the welders adjustments

brought a bolt heat sink & 2 Talley bolt handles from Brownells . Heat blocking putty from the local plumbing supply shop, Made a bolt handle alignment jig

out of material i had laying around. Here is the results the next one will take halve the time & be a better job.