Norbert Hansen

AH member

Monolithic Solids or Monometal Bullets

Decades ago, when the terminal velocities of modern cartridges became faster and more hunters went to Africa for big game hunting, reports on failure of the copper cladded, lead core FMJ bullets became evident (bending, breaking up, fishtailing). That was the time, when the monolithics offered the answer for good performance. There were only minor complaints on the drawbacks: e.g. less penetration in the game, loss of volume for the powder in the smaller cases and some times a ruined rifle due to a mismatch in bore/bullet diameter esp. for older rifles. But today the new generation of steel jacketed bullets with lead or even tungsten cores offers again better performance than the monolithics. (The percentage of weight steel to lead is 50:50)! They are very rigid, no deformation under normal conditions and shooting distances. A monolithic is more susceptible to bending than this FMJs. They are the shortest solids, giving sometimes room for the additional bit of powder needed. They show maximum penetration for normal bullet dimensions and twist rates.

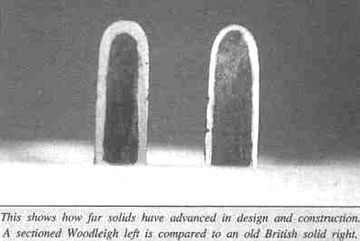

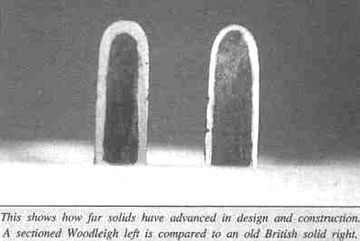

With the right twist and large cases, today monolithic bullets show no problems. They are improved by using better materials (soft copper), driving bands for less fouling and a better gas seal, but sometimes they have one drawback: To customize conventional factory rifles you are often dependent on the magazine capacity. That requires a belted H&H case and restricts the cartridge to .458 Lott, Watts or Ackley or the .470 Capstick. An excellent load is a .458 500 gr at the "magic" velocity of 2400 f/s. I tried hard to find a load with safe pressure and it is only possible with short bullets like Speer or Woodleigh, modern High Energy powders and a little powder compression. There is no room for the extra length of monometals.

There is an increasing number of monometal deforming bullets on the market. They are made from soft copper with some kind of a hollow point nose for a controlled expansion. These bullets are very effective with respect to penetration and creating deep wound channels. But to overcome the drawback of the greater length, manufacturers recommend the use of lighter bullets, the greater muzzle velocity would compensate for the lower mass. This can accepted for normal hunting conditions, but applied to non-deforming bullets (solids) for dangerous game hunting it can become a desaster. The lower sectional density results in less penetration (see Penetration Index), because less weight normally can not compensated by more muzzle velocity in safe pressure limits.

An example for the .458 WinMag:

Which of these bullets would penetrate best, and which is most suitable for a thick skinned animal:

500 grains at 2000 fps?

400 grains at 2500 fps?

350 grains at 2857 fps?

Assume these are .458 caliber non-deforming bullets.

Under ideal condition there would be no difference in penetration, all parameters else are equal. But: With our hunting cartridges it is impossible to compensate mass with velocity in safe pressure limits. Only the 500 grs at 2000 f/s is a realistic choice. To achieve the other velocities the pressure would be as follows:

500 grains at 2000 fps? 3600 bar

400 grains at 2500 fps? 4600 bar

350 grains at 2857 fps? 5800 bar

The maximum pressure (piezo) allowed is 4300 bar, copper crusher 3800 bar

There is another, very important reason to use bullets with a SD greater than 0.3: We don´t know exactly the drag function in animals and it must be very complicated. But one fact is for sure: The heavier bullets are less decelerated than the lighter ones. Heavier bullets loose less velocity during their travel through the target. That means: heavier bullets keep their momentum, lighter bullets loose more momentum on their travel through the body. And keeping momentum results in deeper penetration.

Nowadays also modern nondeforming monometal solids (Flat nose e.a.) are often made from soft copper. They show very stable penetration (see chapter on SuperPenetrator), but hitting very hard bone the may be compressed by the jam pressure and shortened and so loosing some penetration.

About Solids, FMJ and Monolithics

Testing, made by Ch. Haley, African Hunter, Vol.5 No.6 Dec.99 show the good performance of modern FMJ bullets.

Three Bullets, Woodleigh .458, 500 gr, FMJ, recovered from Elephant after frontal headshot.

Momentum

In some publications the thesis is presented, that the momentum is the property to look on for the penetration ability and performance of bullets. That is not possible. The momentum is physically related to the kinetic energy (divided by the velocity) and does not primarily control the penetration. You can proof it: Take a rock of 3 kg from the ground and speed up your walking speed to 5 miles per hour, now it possesses the same momentum as a hot .458 bullet. But throwing it on an animal, it is evident that there will be no effect.

Newton´s law of conservation of the momentum tells us, that after a shot the rifle has the same momentum as the bullet. We know the difference.

Factors governing the penetration of a bullet and why the momentum is not applicable

Neither the kinetic energy nor the momentum are primarily responsible for the penetration ability of a bullet in an animal.

In general, the momentum of a moving body says nothing about its penetration through a medium. Look at the momentum and penetration of an arrow or a slow moving 3 kg rock, or remember the same momentum of a recoiling rifle and the launched bullet. The momentum is useful if we take into consideration the interaction of two bodies, for instance "what makes a silhouette fall". A man can compensate the momentum of a .308 bullet standing on one leg, if he wears a protecting vest. That a charging lion is pushed back in the air by the bullets momentum is a fairy tale. With good body shots an animal falls onto the side of the bullet´s entrance, it is not pushed back by the bullets momentum.

The most important feature for penetration is the momentum density. Momentum density defines the penetration potential of a projectile. Momentum density it defined as the momentum of the projectile divided by the projectile's cross sectional area. The next important feature for penetration is the frontal area and its shape. Because we need energy we have to add weight behind this frontal area and the result is sectional density. Nose geometry is merely a fine tuning, in that is tweaks forces exerted upon the projectiles during flight to keep the projectile stable i.e. no tumbling, yawing off straight path, etc. Therefore, point geometry could have a significant effect on straight line penetration.

A projectile will penetrate, as long as the shear stress exerted by the projectile on the target is greater than the shear strength of the target. Shear stress is defined as the force of the projectile divided by the projectile's cross sectional area. The penetration depth is determined by the interaction with the medium. If there is no interaction, the penetration would be infinite, also if the retarding force is compensated by a rocket engine. The mechanism of the deceleration is very complex and hardly to calculate from basic figures because we do not know the drag functions in the different media a bullet passes going through an animal.

Penetration also depends on bullet construction and deforming bullets (soft nose) sometimes show less penetration at higher velocity because they give more resistance to the medium due to altering their shape. But nondeforming bullets (solids) never can exhibit lower penetration when travelling with higher velocity, all other parameters being equal. But there are still some mysteries about less penetration at higher velocities around, together with arguments presenting erroneous physical statements. First, a simple logic: When the higher velocity bullet decelerates to normal velocity, it further should now penetrate normal.

In summary, more penetration for the high velocity bullet. From physics: The force, which is needed to penetrate, is F=d(m*v)/dt. That means, the force equals the change in momentum with time. And is higher with higher velocity.

If we have a given frontal area and sectional density, the traveling bullet has to compensate for the decelerating forces acting on its surface. This working force (force times way, equals energy) has to be delivered by the kinetic energy of the bullet. That is another important feature for penetration.

For a rough comparison we can use the penetration index. It is calculated from the kinetic energy, sectional density and frontal area.(See table in the main part).

Similar to the comparison of a piece of rock with a bullet is the relation of a small to a big caliber. Here also the momentum is misleading. A .284 cal 175 gr bullet at 2400 f/s compared with a .620 cal 900 gr bullet at 1900 f/s has less than one third energy, a quarter of momentum, but 25 % more penetration. Bullet of same weight (.510 cal 570 gr) at 1900 f/s compared with 2400 f/s : energy plus 50 %, of course momentum goes up 30 % and penetration 50 % .

The .458cal 500gr at 2030 f/s compared with a .458 450 gr 2250 f/s have the same penetration and, by chance?, the same momentum. But the 450 gr is loaded to much higher pressure, 4260 bar instead 3780 bar. If you load the 450gr to the same pressure as the 500 gr the velocity is 2170 f/s and the penetration 8 % lower, the momentum 3 % lower. But these figures are marginal and of no meaning in practice.

Another stringent example, .620 cal 900 gr at 1900 f/s compared with a .510 cal 570 gr at 2400 f/s. Same energy, but 20 % less momentum and 40 % higher penetration!

Decades ago, when the terminal velocities of modern cartridges became faster and more hunters went to Africa for big game hunting, reports on failure of the copper cladded, lead core FMJ bullets became evident (bending, breaking up, fishtailing). That was the time, when the monolithics offered the answer for good performance. There were only minor complaints on the drawbacks: e.g. less penetration in the game, loss of volume for the powder in the smaller cases and some times a ruined rifle due to a mismatch in bore/bullet diameter esp. for older rifles. But today the new generation of steel jacketed bullets with lead or even tungsten cores offers again better performance than the monolithics. (The percentage of weight steel to lead is 50:50)! They are very rigid, no deformation under normal conditions and shooting distances. A monolithic is more susceptible to bending than this FMJs. They are the shortest solids, giving sometimes room for the additional bit of powder needed. They show maximum penetration for normal bullet dimensions and twist rates.

With the right twist and large cases, today monolithic bullets show no problems. They are improved by using better materials (soft copper), driving bands for less fouling and a better gas seal, but sometimes they have one drawback: To customize conventional factory rifles you are often dependent on the magazine capacity. That requires a belted H&H case and restricts the cartridge to .458 Lott, Watts or Ackley or the .470 Capstick. An excellent load is a .458 500 gr at the "magic" velocity of 2400 f/s. I tried hard to find a load with safe pressure and it is only possible with short bullets like Speer or Woodleigh, modern High Energy powders and a little powder compression. There is no room for the extra length of monometals.

There is an increasing number of monometal deforming bullets on the market. They are made from soft copper with some kind of a hollow point nose for a controlled expansion. These bullets are very effective with respect to penetration and creating deep wound channels. But to overcome the drawback of the greater length, manufacturers recommend the use of lighter bullets, the greater muzzle velocity would compensate for the lower mass. This can accepted for normal hunting conditions, but applied to non-deforming bullets (solids) for dangerous game hunting it can become a desaster. The lower sectional density results in less penetration (see Penetration Index), because less weight normally can not compensated by more muzzle velocity in safe pressure limits.

An example for the .458 WinMag:

Which of these bullets would penetrate best, and which is most suitable for a thick skinned animal:

500 grains at 2000 fps?

400 grains at 2500 fps?

350 grains at 2857 fps?

Assume these are .458 caliber non-deforming bullets.

Under ideal condition there would be no difference in penetration, all parameters else are equal. But: With our hunting cartridges it is impossible to compensate mass with velocity in safe pressure limits. Only the 500 grs at 2000 f/s is a realistic choice. To achieve the other velocities the pressure would be as follows:

500 grains at 2000 fps? 3600 bar

400 grains at 2500 fps? 4600 bar

350 grains at 2857 fps? 5800 bar

The maximum pressure (piezo) allowed is 4300 bar, copper crusher 3800 bar

There is another, very important reason to use bullets with a SD greater than 0.3: We don´t know exactly the drag function in animals and it must be very complicated. But one fact is for sure: The heavier bullets are less decelerated than the lighter ones. Heavier bullets loose less velocity during their travel through the target. That means: heavier bullets keep their momentum, lighter bullets loose more momentum on their travel through the body. And keeping momentum results in deeper penetration.

Nowadays also modern nondeforming monometal solids (Flat nose e.a.) are often made from soft copper. They show very stable penetration (see chapter on SuperPenetrator), but hitting very hard bone the may be compressed by the jam pressure and shortened and so loosing some penetration.

About Solids, FMJ and Monolithics

Testing, made by Ch. Haley, African Hunter, Vol.5 No.6 Dec.99 show the good performance of modern FMJ bullets.

Three Bullets, Woodleigh .458, 500 gr, FMJ, recovered from Elephant after frontal headshot.

Momentum

In some publications the thesis is presented, that the momentum is the property to look on for the penetration ability and performance of bullets. That is not possible. The momentum is physically related to the kinetic energy (divided by the velocity) and does not primarily control the penetration. You can proof it: Take a rock of 3 kg from the ground and speed up your walking speed to 5 miles per hour, now it possesses the same momentum as a hot .458 bullet. But throwing it on an animal, it is evident that there will be no effect.

Newton´s law of conservation of the momentum tells us, that after a shot the rifle has the same momentum as the bullet. We know the difference.

Factors governing the penetration of a bullet and why the momentum is not applicable

Neither the kinetic energy nor the momentum are primarily responsible for the penetration ability of a bullet in an animal.

In general, the momentum of a moving body says nothing about its penetration through a medium. Look at the momentum and penetration of an arrow or a slow moving 3 kg rock, or remember the same momentum of a recoiling rifle and the launched bullet. The momentum is useful if we take into consideration the interaction of two bodies, for instance "what makes a silhouette fall". A man can compensate the momentum of a .308 bullet standing on one leg, if he wears a protecting vest. That a charging lion is pushed back in the air by the bullets momentum is a fairy tale. With good body shots an animal falls onto the side of the bullet´s entrance, it is not pushed back by the bullets momentum.

The most important feature for penetration is the momentum density. Momentum density defines the penetration potential of a projectile. Momentum density it defined as the momentum of the projectile divided by the projectile's cross sectional area. The next important feature for penetration is the frontal area and its shape. Because we need energy we have to add weight behind this frontal area and the result is sectional density. Nose geometry is merely a fine tuning, in that is tweaks forces exerted upon the projectiles during flight to keep the projectile stable i.e. no tumbling, yawing off straight path, etc. Therefore, point geometry could have a significant effect on straight line penetration.

A projectile will penetrate, as long as the shear stress exerted by the projectile on the target is greater than the shear strength of the target. Shear stress is defined as the force of the projectile divided by the projectile's cross sectional area. The penetration depth is determined by the interaction with the medium. If there is no interaction, the penetration would be infinite, also if the retarding force is compensated by a rocket engine. The mechanism of the deceleration is very complex and hardly to calculate from basic figures because we do not know the drag functions in the different media a bullet passes going through an animal.

Penetration also depends on bullet construction and deforming bullets (soft nose) sometimes show less penetration at higher velocity because they give more resistance to the medium due to altering their shape. But nondeforming bullets (solids) never can exhibit lower penetration when travelling with higher velocity, all other parameters being equal. But there are still some mysteries about less penetration at higher velocities around, together with arguments presenting erroneous physical statements. First, a simple logic: When the higher velocity bullet decelerates to normal velocity, it further should now penetrate normal.

In summary, more penetration for the high velocity bullet. From physics: The force, which is needed to penetrate, is F=d(m*v)/dt. That means, the force equals the change in momentum with time. And is higher with higher velocity.

If we have a given frontal area and sectional density, the traveling bullet has to compensate for the decelerating forces acting on its surface. This working force (force times way, equals energy) has to be delivered by the kinetic energy of the bullet. That is another important feature for penetration.

For a rough comparison we can use the penetration index. It is calculated from the kinetic energy, sectional density and frontal area.(See table in the main part).

Similar to the comparison of a piece of rock with a bullet is the relation of a small to a big caliber. Here also the momentum is misleading. A .284 cal 175 gr bullet at 2400 f/s compared with a .620 cal 900 gr bullet at 1900 f/s has less than one third energy, a quarter of momentum, but 25 % more penetration. Bullet of same weight (.510 cal 570 gr) at 1900 f/s compared with 2400 f/s : energy plus 50 %, of course momentum goes up 30 % and penetration 50 % .

The .458cal 500gr at 2030 f/s compared with a .458 450 gr 2250 f/s have the same penetration and, by chance?, the same momentum. But the 450 gr is loaded to much higher pressure, 4260 bar instead 3780 bar. If you load the 450gr to the same pressure as the 500 gr the velocity is 2170 f/s and the penetration 8 % lower, the momentum 3 % lower. But these figures are marginal and of no meaning in practice.

Another stringent example, .620 cal 900 gr at 1900 f/s compared with a .510 cal 570 gr at 2400 f/s. Same energy, but 20 % less momentum and 40 % higher penetration!

Last edited by a moderator: